November 7, 2023

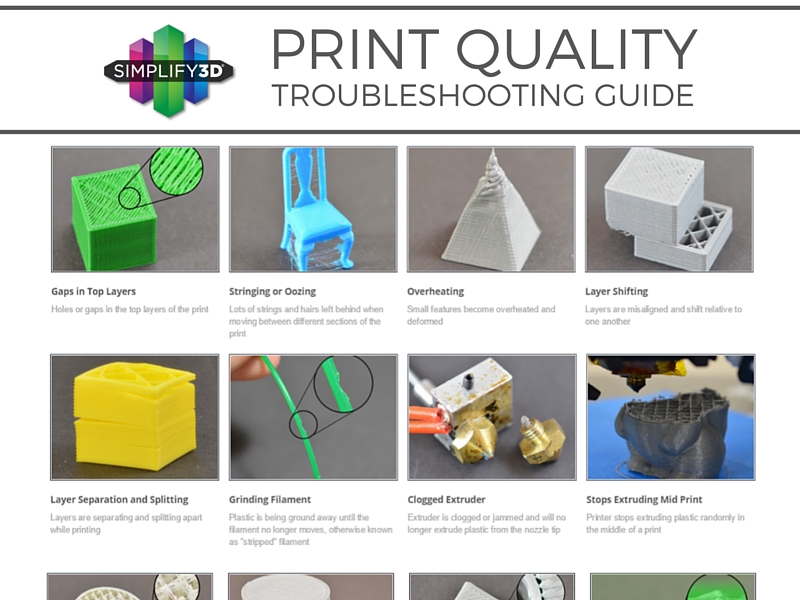

3d Printing Troubleshooting Overview

3d Printing Troubleshooting: All Issues & Services Software-generate sustains can be intrusive to your print and also the filament might be embeded the locations where it's difficult to get rid of. Making the supports by yourself is an excellent way to deal with that, although you need to have some skill. The motion being not smooth as well as the too much tool vibration are common signs too. In this instance, power off the printer, move the head flat and locate where your bearings are broken or worn off. Disable the stepper electric motors and even power off the gadget completely and relocate the print head manually with a little force in the horizontal axes.How do you understand if PLA filament misbehaves?

Make Sure You Are Printing On A Solid Base

We're uncertain why this is; some presume hotter temperature levels will improve flow rate. We always recommend starting at the lowest factor in the recommended range as well as work your method up in 5 ° C increments, if needed. You might be publishing as well cold for the desired print speed. Printing much faster or at greater extrusion prices calls for even more warmth to melt the correct amount of plastic in time. Boost your temperature in 5 ° C increment examinations until the concern is settled.- Some filaments bring in and also absorb wetness from the air at very high prices.

- If you've got a 3D printing problem, challenge or concern, our group is below to help.

- Additionally, reduce the temperature level when the printer is coming close to the problem area.

- Make sure to add a drop of oil on tidy rods considering that they need lubrication.

Your Print Does Not Stay With The Bed

Clear pictures of the problem, screengrabs of the layer sight in your slicer, screengrabs of the version itself. In the video clip below by Stefan from CNC Cooking area, he procured eliminate these balls by adjust the Maximum Resolution embeding in Cura, from the previous default of 0.05 to 0.5 mm. The default presently is 0.25 mm so it might not have the very same degree of impact, yet it can still be a prospective solution. Picking a certain location for your Z joint can help with this concern. The Z joint is primarily where your nozzle will start at the start of each new layer, creating a line or seam that shows up on 3D prints. Making it possible for retractions is one more technique of taking care of balls & acnes in your 3D prints.3D Printed Home Made with All Bio-based Materials Unveiled by UMaine - 3DPrint.com

3D Printed Home Made with All Bio-based Materials Unveiled by UMaine.

Posted: Wed, 23 Nov 2022 08:00:00 GMT [source]

Social Links