November 22, 2023

Troubleshooting Guide

Troubleshooting & Products 3d Printing Additive Manufacturing Sbu Collections At Southwest Baptist College Libraries You're seeing wisps or strings of extruded plastic on the outside surface area of the completed part that are not a component of the initial design. Some can be gotten rid of easily, while others need to be reduced or scraped off. They can wreck a print by making it look much less than best, however this commonly occurs with versatile filaments. Including even more support frameworks is one more solution, though you'll need to address the concern of boosted post-processing clean up routine after you finished the printing.- Tell your slicer to print the lays out before doing the infill.

- Environmental variables - A draft blowing over the printer from an open home window may affect print attachment.

- These variations in layers are frequently a result of temperature level fluctuations.

- Most slicers have a rate setting just for layer one, so you can ensure good adhesion without decreasing the subsequent layers.

- A bridge can be efficiently printed by tactically placing assistances along the period of the bridge.

Print Troubleshooting

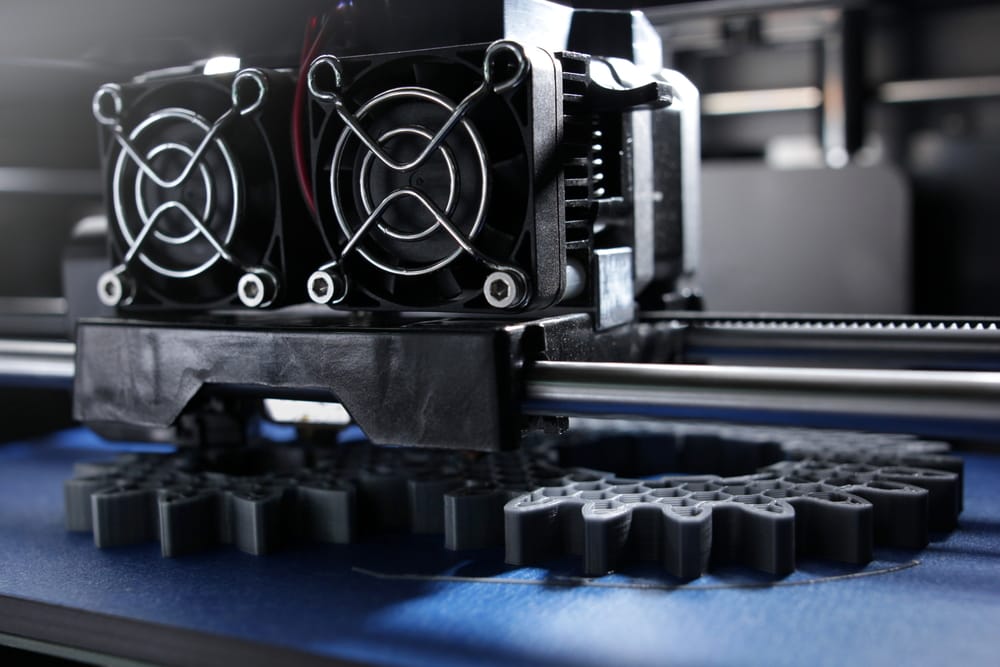

If the filament is unable to cool quick sufficient it will certainly be impossible for it to cover long distances and also as a result give proper connecting. Be sure to preserve ideal extrusion speed, considering that a fast-moving print head will definitely trigger resonance that in its turn will certainly cause instability prior to filament setting. The last remedy would be to inspect if one of the poles might have gotten flawed. Make certain to transform your printer off as well as examine the printed head by hand, moving it in X-Y axes. If the head isn't relocating free, look for correct poles alignment.Micro Metal 3D Printing – the New Investment Magnet - 3DPrint.com

Micro Metal 3D Printing – the New Investment Magnet.

Posted: Tue, 28 Mar 2023 07:00:00 GMT [source]

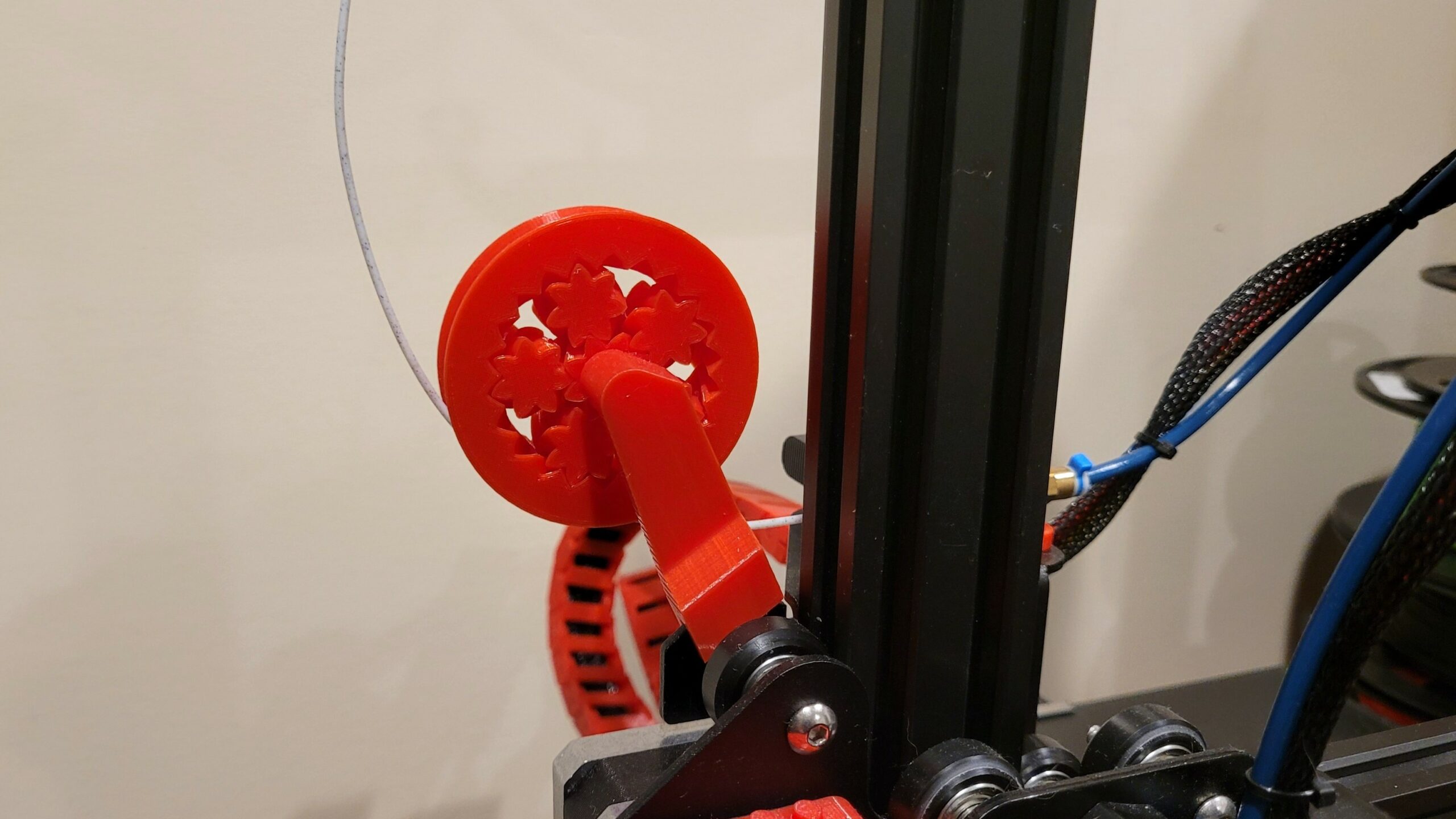

Stringing

Inadequate air conditioning-- if in any way feasible, boost air conditioning during the printing of these parts of the things. Always examine this is suitable for the material you're using with the maker. here This allows the extruded plastic to cool even more before the following pass of the nozzle. If kept also cozy, the layer will peel off back where it was printed. Much better cooling boosts linking performance, and that's basically what we're doing when publishing over infill. ABS is highly vulnerable to 3D printer layer separation as a result of cold air hitting the print before it has actually cooled completely.What should I check prior to 3D printing?

You'll likewise see that when PLA spoils, it obtains breakable as well as easily snaps off.

HP Unveils New 3D Printer for Dyeable White Parts, New Metal 3D Printed Parts for John Deere - 3DPrint.com

HP Unveils New 3D Printer for Dyeable White Parts, New Metal 3D Printed Parts for John Deere.

Posted: Mon, 14 Nov 2022 08:00:00 GMT [source]

Social Links