November 7, 2023

Secure 3d Printing The Brand-new Disruptive Modern Technology As Well As Watch The Market Expand

New 3d Printing Method Prepared To Progress Production " The chemical conversion of the material and all other examinations will certainly also have to be accomplished inside the chamber," Momotenko explains. 3D printing is a wide term that consists of a collection of numerous different sorts of 3D printing as reviewed earlier. Various other co-authors are from Sungkyunkwan University and also Digital Light Innovations.What is the best 3D printing approach?

Polycarbonate. According to numerous manufacturers and customers, polycarbonate (PC) is taken into consideration the best customer filament around. Computer can produce incredibly high-strength components when published appropriately with an all-metal hot end and also a room.

Popular 3d Printing Post-processing Strategies

Designers have created an extremely effective method to paint intricate 3D-printed objects, such as light-weight frameworks for airplane and biomedical stents, that could conserve producers money and https://sgp1.vultrobjects.com/large-format-printing-services/Graphic-Software/design-inspiration/13-means-exactly-how-to-improve-3d-print-high-quality-with-ease.html time and also ... Researchers have created a low-cost multiple-use support approach to minimize the demand for 3-D printers to print wasteful supports, greatly improving cost-effectiveness as well as sustainability for 3-D ... Furthermore, since the nozzles can be switched on as well as off independently, an MF3 printer has built-in resiliency, making it much less vulnerable to costly downtime, Cleeman said. In the pictures listed below, we've set out a few of the more beautifully made complex styles developed utilizing a 3D printing procedure called Laser Sintering. These 3D published designs are involved, and also yet the part can be constructed in a consolidated device. Through 3D printing, free-flowing, organic and also detailed layouts are effortlessly carried out while maintaining strength in means difficult via any kind of various other manufacturing process. A couple of models later on and also you and also your group arrive on it, the perfect design.Top 6 Markets Utilize 3d Printing: A Vast Array Of Industrial Applications

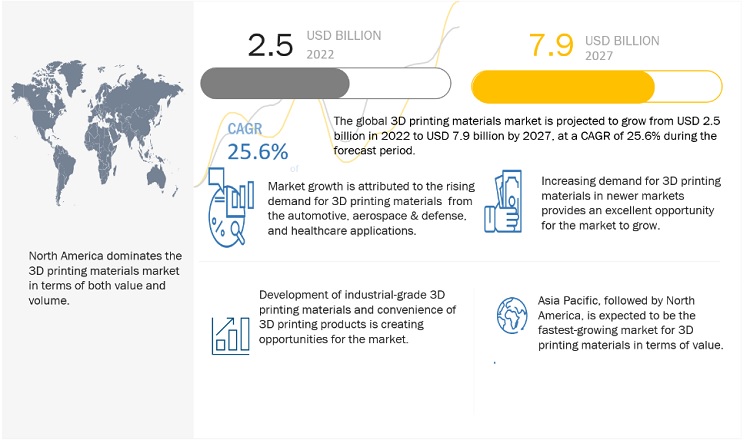

Right here are several of the locations where 3D print technique is playing an integral part to drive advancement as well as growth. Also after that, thermoplastics are amongst one of the most popular products for 3D printing modern technologies today. Acrylonitrile Butadiene Styrene, Polylactic Acid, PolyCarbonate, and Polyvinyl Alcohol are some of the most common selections across different industries due to their adaptability as well as ideal features.- Charter Road has actually a predicted spending plan of ₤ 6m, an estimated 25% price reduction against equivalent building.

- The consolidation of micro-channels efficiently distributed additional seeding surfaces throughout the interior of the device, boosting the reliable seeding density and also uniformity.

- The product is transferred in one lengthy continual strand or in individual dots from a nozzle or syringe to develop a desired 3D shape of ceramics, polymers, or hydrogels.

- HP Jet Blend 3D Printing Solutions using HP 3D High Reusability PA 12 give up to 80% powder reusability ratio, generating practical parts set after set.

SPEE3D celebrates success in US defense challenge with Cold ... - TCT Magazine

SPEE3D celebrates success in US defense challenge with Cold ....

Posted: Thu, 18 May 2023 07:00:00 GMT [source]

Social Links