November 7, 2023

3d Printing Troubleshooting: All Issues & Options

44 Usual 3d Print Issues Fixing Issues 2023 With a lot of slicers, the infill is published at the highest possible print speed specified, while lays out for instance are printed slower. So, the top place to discover expensive print rates is typically the infill. Lower your print speed slowly to test if this repairs the concern as you might be printing also fast. You'll experience infill issues if you're trying to make use of a layer elevation that is too expensive for your nozzle or extruder. Adhere to an optimum layer height of 75% of your nozzle size (i.e. 0.3 mm for a 0.4 mm nozzle).3DQue’s QuinlyVision Automates 3D Print Failure Detection - 3DPrint.com

3DQue’s QuinlyVision Automates 3D Print Failure Detection.

Posted: Mon, 13 Jun 2022 07:00:00 GMT [source]

Recap Of Remedies: Poorly Developed Bridges

In some cases something like an ABL probe will certainly be fitted quickly, before the individual recognizes just how to manually level the bed. The thrill to update denies the user of learning the basics required for reliable as well as effective long-term operation. To prevent wetness shop your filament dry, this is why we at rigid.ink give unique Mylar resealable bags with each order. If your printer is confined, open all doors, side panels or top covers to maintain the ambient temperature down. Also the very best fans are inefficient if all they're doing is relocating hot air around. Overhangs are where you're publishing an inclined surface area with no support under. This function has a pre-defined collection of parameters that can be changed in order to manage the printing process even more. For example, you may want to customize minimum travel considering that it https://s3.us-east-1.amazonaws.com/custom-printing/Large-Format-Printing/printing-techniques/3d-printing-pointers-for-novices-exactly-how-to-3d-print-a-practical-looking.html will most likely take care of the stringing if laid-back activation of retraction didn't assist. The extruder nozzle may be blocked due to numerous factors. Look for any kind of remains of excess filament or dust inside the nozzle, considering that it may restrict the printed product access. After that print a calibration cube and also confirm that the filament is squeezing out appropriately as well as the problem is gotten rid of.- If there's no material to make use of, the printer won't work, so you can place a new spool and also try to rerun the print.

- It decreases just how rapidly the model cools down given that the temperature around the extruded filament is higher.

- Examine the rigidity as well as appropriate positioning of your printer frame.

- This could be any of the benign factors like printing too chilly, or also hot, or too fast, utilizing too much retraction or nozzle to near the bed, and so on.

- Some added lines of filament can trigger your print to look different than it should.

- The first point to do if you experience over extrusion is to reduce your printing temperature level so filament doesn't flow through so conveniently.

Understanding The Updated Printhead Cover For Epson Xp-15000: A Thorough Guide

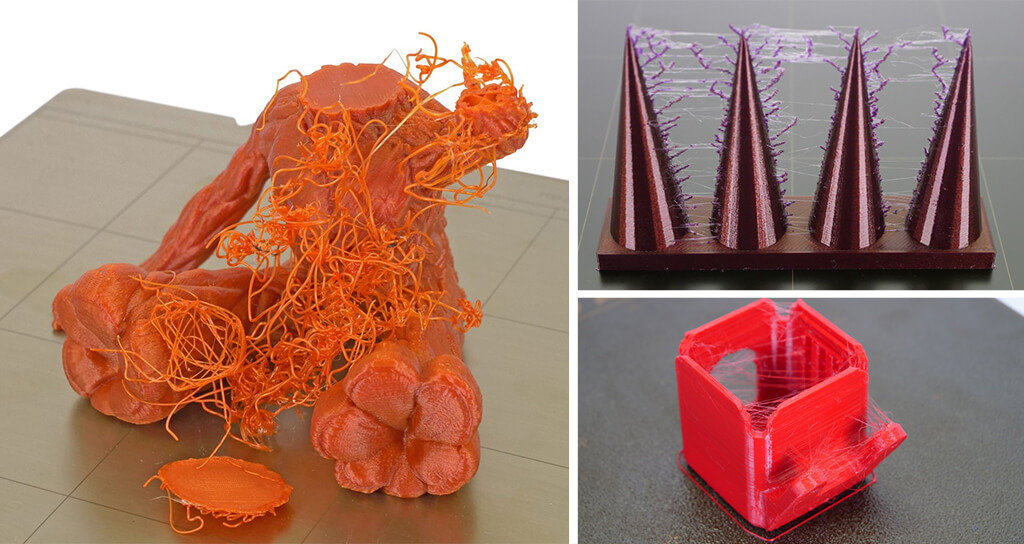

Stringing is an usual problem that individuals face when 3D printing. It's a print flaw that creates lines of strings across a 3D print. They ought to generate a rather low/deep noise when tweezed.The State of Open-source 3D Printing: How to Preemptively Quash Patent Parasites and Trolls - 3DPrint.com

The State of Open-source 3D Printing: How to Preemptively Quash Patent Parasites and Trolls.

Posted: Mon, 03 Apr 2023 07:00:00 GMT [source]

What should I inspect before 3D printing?

You'll additionally discover that when PLA goes bad, it gets fragile as well as conveniently snaps off.

Social Links