November 7, 2023

Print High Quality Overview

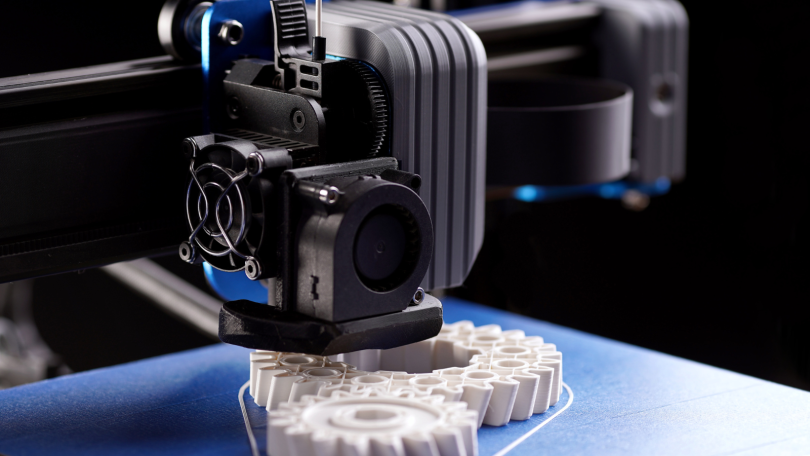

Print Troubleshooting Photographic Overview If fast printing is a decisive facet of your production and also can not be transformed, attempt increasing the circulation and also extrusion temperature level. With no problems, it generates one premium detail after an additional. But when it concerns printing a fine information, the final product has a great deal of misprints.- Some 3D printing concerns like this, appear as totally random as well as separated events.

- You may have the ability to see the problem as well as untangle the knot or eliminate a layer or two if there is a twist.

- To prevent this trouble, you ought to unblock the nozzle routinely.

- Thoroughly check out among the couplers and locate a small-scale collection screw.

- Some printers will not relocate some axes till the printer is homed.

Recap Of Remedies: Stripped Filament

We wish that our list of the 10 most usual 3D printing troubles and also options comes in handy. You need to make it even to fix these 3D print problems. Or you have to adjust your nozzle height to get rid of the filament "pastas" insect. It is also feasible to use a layer of glue or various other attachment to the system to help the print stay with the bed. Problem Common Reason Modification Forum Link printer head fails to maintain its setting Click for source as well as prints succeeding layers counter from lower layers. Stepper controllers with their potentiometers changed also reduced (counter-clockwise), triggering stepper to miss out on steps.3D Printing Financials: Velo3D Misses Earnings and Adjusts Full Year Guidance - 3DPrint.com

3D Printing Financials: Velo3D Misses Earnings and Adjusts Full Year Guidance.

Posted: Wed, 09 Nov 2022 08:00:00 GMT [source]

Leaning Of Print

Examine the filament path is tidy, specifically if utilizing a Bowden tube. If your Bowden tube or an additional part has actually become worn it might need replacing. You may have the ability to see the problem and also disentangle the knot or eliminate a layer or more if there is a kink. If you can not see the problem but your spindle will certainly not unspool conveniently, or it is repeatedly taking place, please see our post.What are the common 3D printing troubleshooting issues?

- Not Extruding at Beginning of Publish. Printer does not extrude plastic at the beginning of the print.Not Sticking to the Bed.Under-Extrusion. Over-Extrusion.

- Gaps in Leading Layers.Stringing or Oozing.Overheating.Layer Shifting. Dimension.

- One feature to consider when

- developing your item is it's scale.The resolution.

- During additive manufacturing, the resolution describes the density of each layer of product being'applied.Wall thickness.The orientation.The option of

- material.Design equilibrium. When a PLA filament takes in moisture, it swells up, increasing the danger of extruder jams. Wetness likewise triggers PLA to produce prints with bubbles and voids externally, as a result destroying your prints

- .

Aussie 3D Printed Electronics Startup Snags $2.5M - 3DPrint.com

Aussie 3D Printed Electronics Startup Snags $2.5M.

Posted: Fri, 06 Jan 2023 08:00:00 GMT [source]

Social Links