November 22, 2023

Safe And Secure 3d Publishing The Brand-new Turbulent Modern Technology And Watch The Marketplace Grow

3d Printing Strategies: Various Types Of 3d Printing When analyzing potential producing companions, business take a variety of criterion right into account. Style abilities top the listing yet ability to range, prices and also experience all comply with closely behind. When it comes to main use, the inconsistency between plastic and also metal 3D printing isn't as large as you may assume. More than a 3rd of respondents answered that they utilize plastics as well as steels similarly, and also also in between those that chose either plastics or metals, plastics led by just a little over 10%. When we performed our very first survey, a lot of the advantages were still intangible ideas.Which modern technologies are currently used in 3D printing?

- Product Extrusion.Fused Deposition

- Modeling( FDM) 3D Bioprinting.Construction 3D Printing.Vat Polymerization.Stereolithography (SLA)

- Digital Light Processing( DLP) Liquid Crystal Present( LCD)

Careful Laser Sintering (sls)

Column job Doka For an office building near Munich, Deutsche Doka once again utilized 3D published formwork elements from voxeljet for concrete casting. For medical 3D printing that takes place outside the extent of FDA regulation, little official oversight exists. State clinical boards might have the ability to exert some oversight if 3D printing by a specific company is putting clients in jeopardy; however, these boards commonly respond to filed problems, instead of perform aggressive investigations. 3D printing as well as additive manufacturing supply many advantages to the production process. The brother or sister of Discerning Laser Melting, Direct Power deposition additionally utilizes a laser as well as metal powder to fabricate metal parts. We have actually detailed why 3D printing is deemed a game-changer for manufacturing in the following section, consisting of exactly how 3D printing has transformed prototyping as well as manufacturing through cost, preparation and layout liberty. We will certainly dig deeper into why modern technologies need supports-- as well as which ones do not-- when we burst out right into private 3D printing processes. ] has been seen with the statement of the initial 3D printed structure, utilizing a premade 3D printed elements made by Winsun, which declared to be able to publish 10 houses in a day with its modern technology. One of the primary purposes of post-processing is to improve the appearance of published things. For instance, the FDM 3D printing procedure creates noticeable layer lines on the surface of parts, detracting from their general aesthetic quality. Yet post-processing strategies such as sanding, brightening, and painting can properly remove or lessen these lines, resulting in a smoother and more professional-looking surface. In 2003, Rupert Soar protected financing as well as created the freeform building team at Loughborough College, UK, to check out the capacity for up-scaling existing 3D printing techniques for building applications. In 2005, the team protected moneying to build a large construction 3D printing machine utilizing 'off the rack' elements to explore just how complex such parts might be and reasonably satisfy the demands for building. HP Jet Fusion 3D Printing Solutions utilizing HP 3D High Reusability TPA enabled by Evonik offer approximately 80% powder reusability proportion, generating practical parts batch after batch. For screening, product is matured in actual printing problems and also powder is tracked by generations. Parts are after that made from each generation as well as checked for mechanical homes and precision. HP Jet Combination 3D Printing Solutions making use of HP 3D High Reusability PA 12 provide approximately 80% powder reusability ratio, producing practical parts batch after set. Though it has actually been around for decades, additive production is still a fairly brand-new technology contrasted to conventional production.Recent Breakthroughs In 3d Printing Of Biomaterials

A lot of what we publish often tends to be units as well as there are some excellent ideas for those drifting around. However if you are simply starting, you must look into's video of things he desired somebody had told him when he began 3D printing. Preparing a part for a develop is mostly automated with some hand-operated interaction to excellent part orientation or support production.- Due to extreme handling conditions of SFF techniques (e.g. heat, natural solvent), biochemical particles are not normally integrated directly right into the scaffold.

- What is 3D printing and where are their feasible applications and what is it really with the ability of?

- In vitro researches with bovine chondrocytes for articular cartilage cells design, bone tissue design, monocytic cells from the RAW 264.7 cell line, human osteoblasts, C2C12 pre-myoblastic cell line, and bone marrow stromal cells.

- The low-carbon housing was published by 2 huge integrated arms from a mix of locally sourced dirt and water along with fibers from rice husks and a binder.

- One method you can take to aid you determine based on the main restraints of your project.

What Is 3d Printing And Also What Is Additive Manufacturing?

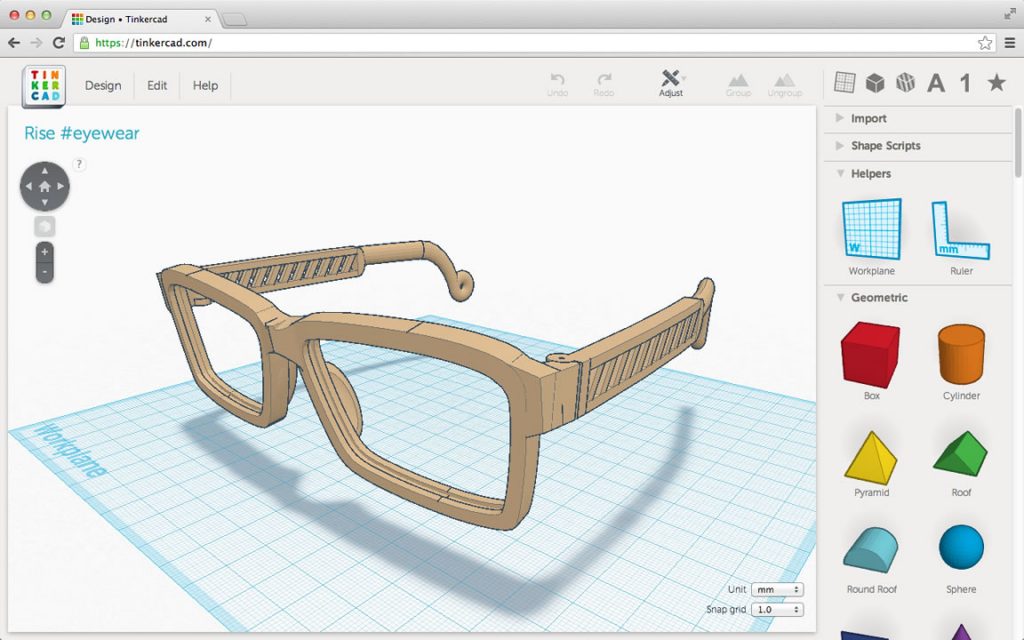

If, on the other hand, you're making components from scrape, it is essential to understand DFM concepts for 3D printing in addition to some basic CAD (Computer-Aided Layout) skills. Industrial applications are the expensive uses, however there are lots of points you can make with a 3D printer at home as well. Online systems like Thingiverse keep considerable directories of cool things to 3D print. Find out all out regarding this flexible manufacturing technology that remains to develop as well as obtain brand-new applications.Advanced 3D Printing Tips - Hackaday

Advanced 3D Printing Tips.

Posted: Fri, 17 Mar 2023 07:00:00 GMT [source]

.jpg)

Social Links