November 22, 2023

3d Printing Layout Tips

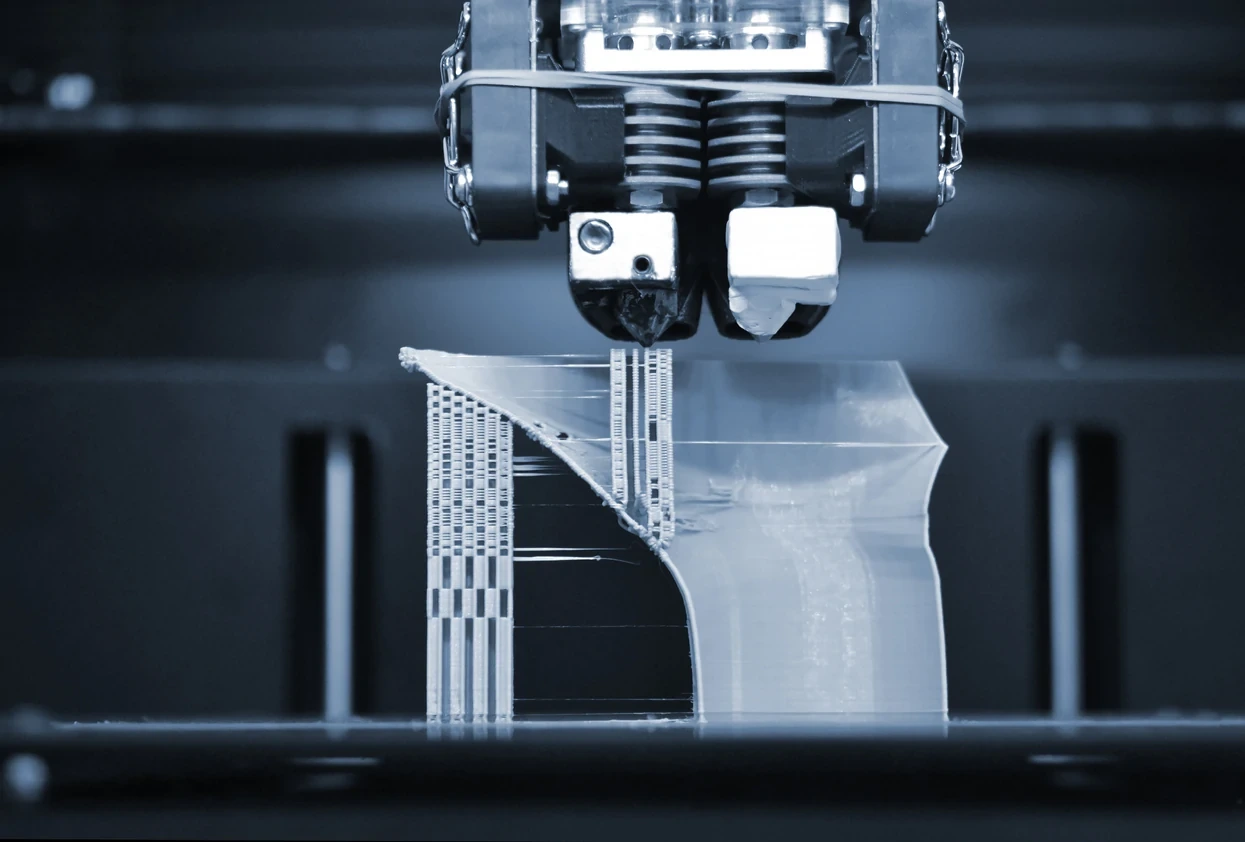

30 Vital 3d Printing Tips For Beginners Ideal Outcomes I get a lot of concerns daily where people ask me about my prints, and just how they can boost print high quality for their 3D printer. I likewise obtain asked about just how I manage to reach the level of quality usually seen in my printed versions. Your print surface area can be perfectly flat as well as degree, but plastic will not stay with it if it's not clean.Man 3D Prints Entire San Francisco City in Homage to Beloved ... - The San Francisco Standard

Man 3D Prints Entire San Francisco City in Homage to Beloved ....

Posted: Sat, 26 Nov 2022 08:00:00 GMT [source]

Criteria For Picking The Very Best 3d Printers For Elementary Schools

Gambody-- Costs 3D printing marketplace intends to share pointers for printing versatile filament. Follow our guide to make your new work of arts look gorgeous, boast all the detailed details and also thrill everyone with a skillful work. Printing too reduced, or with way too much circulation rate can likewise make your prints stick too well on your construct plate potentially damaging your print surface area.Exactly how do I get a good surface area finish in 3D printing?

Minimize First Layer Speed For Much Better Attachment

Now that the bed is correctly leveled, we can move https://us-southeast-1.linodeobjects.com/custom-printing/Packaging-Design/printing-glossary/best-3d-printing-filament-in-2023-pla-abdominals.html to the action which is adjusting the Z countered. Some printers have a Z offset calibration in their menu that makes this process a little bit easier, however I usually do it by following the superb overview from 3DMakerNoob. Eliminate any type of filament put in the nozzle, to prevent oozing during the progressing procedure.- You can dry it making use of special filament dryer boxes, or you can pop it in the oven for some time for the dampness to dry out off.

- A strong 3D print is one that does not collapse on usage, which makes knowing just how to make strong 3D prints.

- There isn't any type of method you can fairly compare both products.

- By observing the skirt high quality, you can readjust any type of leveling problems prior to printing your version.

- It has a budget friendly price, is easy to use, and has a cam to keep an eye on printing.

For Friday: Begin With Energy Efficiency, A Strategy For Cybersecurity And A Study Regarding Technology Needs

Definitely essential when attempting to 3D design parts that have to suit specific locations, or when you simply require an idea of exactly how large a 3D model really is. Brass is soft enough to not mar your nozzle when it needs to be cleaned of any buildup. MatterControl includes adjustable assistance that permits you to highlight as well as delete particular areas of support. We have actually reviewed this in a previous article, so if you want an extra extensive check out just how to transform a nozzle, you can find that below. When you see filament appeared, gently draw on it to remove it from the extruder.3D Printing Blueprints And Other Wall Art - Hackaday

3D Printing Blueprints And Other Wall Art.

Posted: Fri, 19 May 2023 07:00:00 GMT [source]

Social Links