November 7, 2023

Print Quality Guide

The 12 Most Common Troubles In 3d Printing As Well As How To Fix Them This can happen because of a few setups being a little off but check out listed below for exactly how to repair it. Typically, not extruding correctly at the start of a print is a result of the nozzle being also close to the bed or concerns mentioned in the sections over. Or it can simply refer you having changed the extrusion multiplier for a current print as well as neglected to reset it in your slicer. Additionally, really typically the origin for consistent under-extrusion is a partially clogged nozzle. You already attempted [Under extrusion takes place when your printer is not able to supply the correct quantity of material required to properly print a layer. For instance beginning at a common 0.2 mm layer height, try 0.15 mm or even 0.1 mm layer height.Israeli Company Creates 3D-Printed Fish - VOA Learning English

Israeli Company Creates 3D-Printed Fish.

Posted: Tue, 09 May 2023 21:56:39 GMT [source]

6 Great 3d Printing Troubleshooting Guides

Often caused by retraction setups, additional filament balls out and also onto the print. A momentary problem with the filament not unspooling easily may have blocked the motion of the extruder causing your 3D printer moving layers. Trying to print also quickly will trigger the motors to skip, leading to 3D printing layer moving. You can be attempting to print utilizing a layer height that is expensive for your nozzle. If several of the cords do not, there is an interior break and also the cable demand to be changed. The image listed below programs the red cable to be great yet the black cord to be damaged. If there is no connection measured with the multimeter after that there is no chance the signal can be transmitted correctly from the switch to the mainboard. Appropriately configuring endstops, filament runout sensors as well as probes to cause appropriately can be really discouraging unless we understand a good series to comply with.Enable Retractions

You may likewise experience some odd misprinted locations that most definitely weren't on the sneak peek. For example, the Ultimaker 2 has actually eight pulleys linked to the primary horizontal rods. It is a straightforward repair, however occasionally the grub screws are not quickly obtainable. Initially, you need to identify which wheel triggers the concern and then attempt to get accessibility. The result looks generally good, but you can see the rundown of the infill with the walls from the outside. You will likewise see if the nozzle is as well close or too expensive.What are the common 3D printing troubleshooting issues?

- Not Extruding at Start of Publish. Printer does not squeeze out plastic at the beginning of the print.Not Sticking to the Bed.Under-Extrusion. Over-Extrusion.

- Spaces in Top Layers.Stringing or Oozing.Overheating.Layer Shifting. Dimension.

- One attribute to take into consideration when

- creating your product is it's scale.The resolution.

- During additive manufacturing, the resolution describes the thickness of each layer of product being'applied.Wall thickness.The orientation.The option of

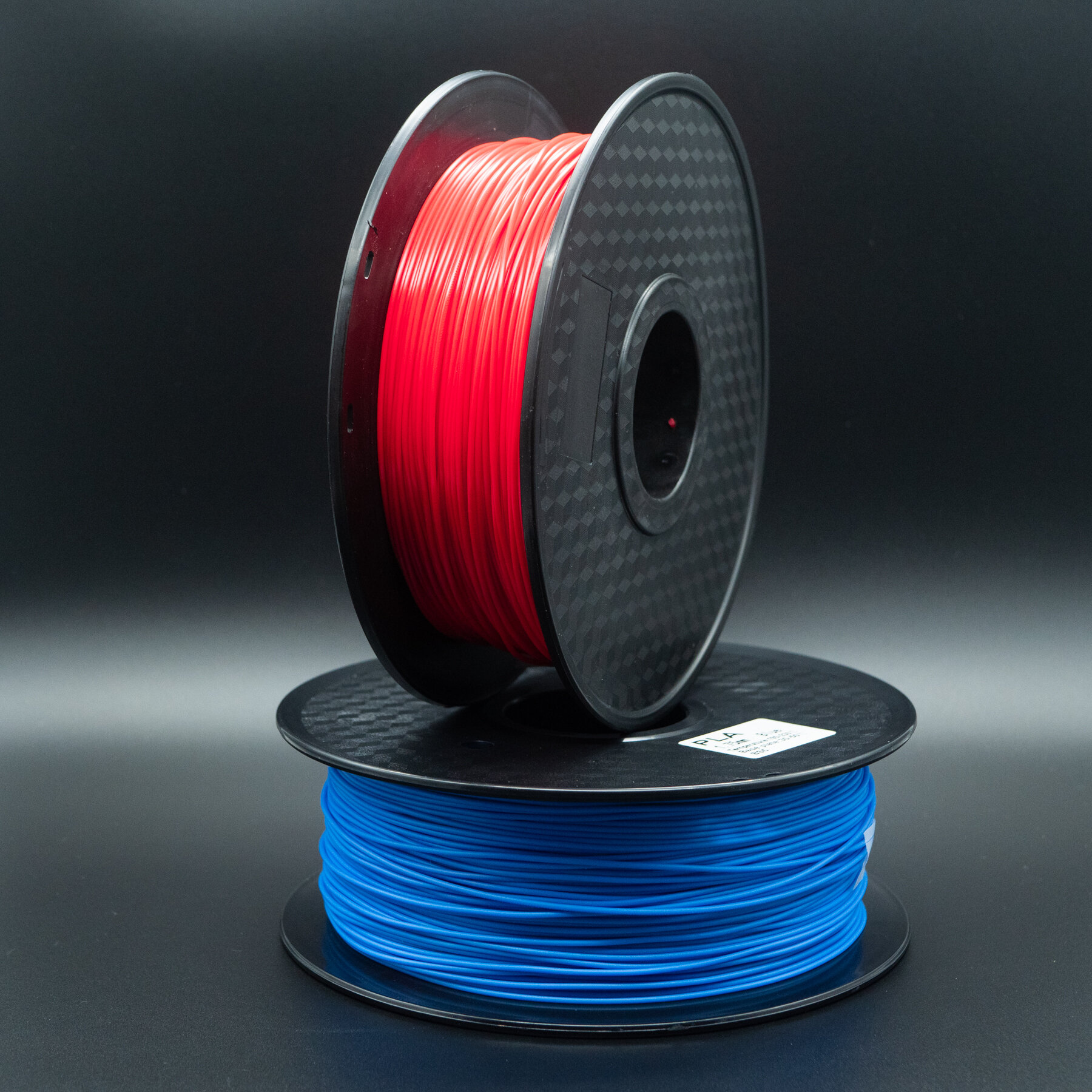

- material.Design balance. When a PLA filament soaks up dampness, it inflates, increasing the risk of extruder jams. Wetness also causes PLA to produce prints with bubbles as well as voids on the surface, for that reason spoiling your prints

- .

Recap Of Options: Inaccurate Dimensional Precision Of A Published Design

The View website proper and also persistent upkeep of your 3D printer will considerably decrease the opportunity of such issues ever showing up. Also before the blockage appears throughout maintenance you can typically locate particular symptoms such as old filament that is currently carbonized being visible inside the nozzle. It can be stuck there for a long period of time, just slightly influencing the quality of prints. The same result can be attained by reducing the print bed, although not every printer has the choice. But this is an extra intricate treatment that needs recalibration and also bed leveling.- Sometimes little items of filament or particles can obtain stuck within the nozzle on the print head.

- Very first thing to try is to remove the filament in the typical manner.

- As the name implies, retraction aids the filament to stay inside the nozzle by withdrawing it before relocating the head.

- I 'd suggest taking the PTFE tube out as well as having a proper take a look at it.

Social Links