November 7, 2023

The Supreme Guide To 3d Printing Post-processing Methods

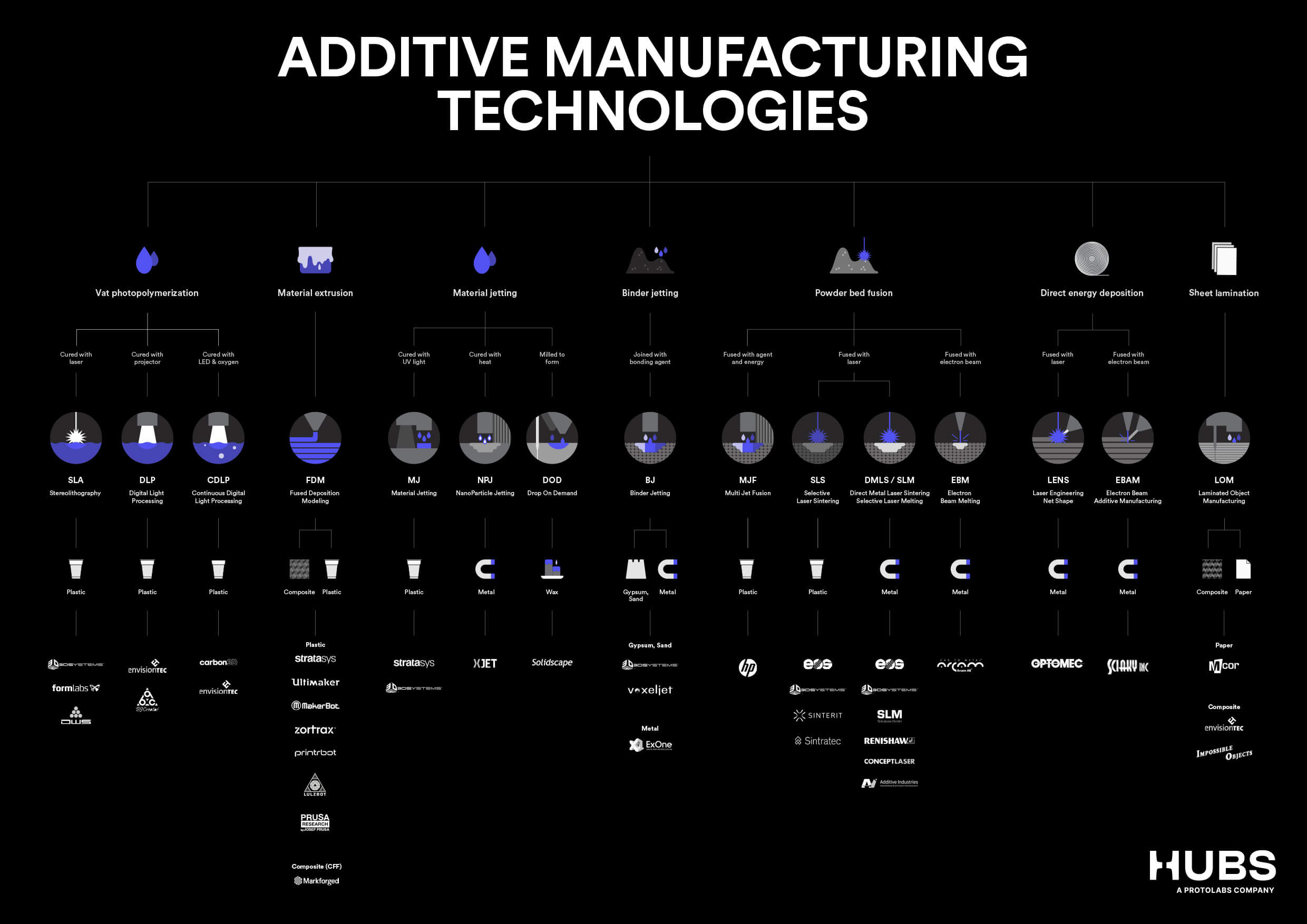

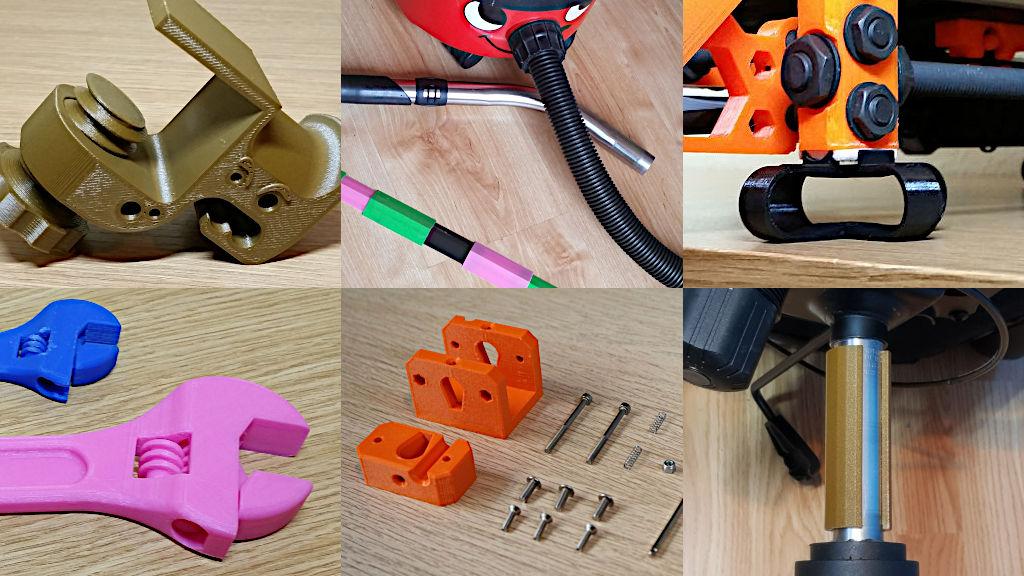

New 3d Printing Strategy Ready To Progress Manufacturing • Merged Deposition Modeling-- FDM printers melt a plastic filament and deposit it onto a construct plate layer by layer. FDM is a basic, economical 3D printing technology appropriate for educational as well as house use. On the one hand, the highly personalized production of unique items and also tiny as well as really little batches will certainly once more ended up being effective and also economically interesting. On the various other hand, durable, high-performance 3D production systems are permeating locations that up until recently were booked for typical making processes.What is the toughest 3D printing approach?

Polycarbonate. According to multiple suppliers as well as reviewers, polycarbonate (PC) is considered the strongest customer filament available. PC can produce incredibly high-strength components when printed correctly with an all-metal hot end and an enclosure.

Voxeljet 3d Printing Systemsincrease Your Efficiency

The capacity to layout and make facility, 3D biomedical devices is critical in cells design. Applications for 3D biomedical gadgets are remediation of 3D structural flaws, the repair of complex organs with complex 3D microarchitecture (e.g. liver, lymphoid organs), as well as scaffolds for stem cell distinction. An instance of a demand is anatomic flaws in the craniomaxillofacial complicated triggered by cancer, trauma, and also hereditary issues. Appropriate remediation of these defects calls for useful nerves, vessels, muscular tissues, ligaments, cartilage material, bone, lymph nodes and also glands. Numerous 3D-printed components outlive options developed making use of much more traditional methods, even in harsh commercial settings.Cyber Threat Intelligence Market Share Size 2023 : Top Players ... - Digital Journal

Cyber Threat Intelligence Market Share Size 2023 : Top Players ....

Posted: Fri, 09 Jun 2023 10:45:23 GMT [source]

Printed Architectural Kinds

When the part is adequately prepared, an appropriate primer, such as an auto filler primer or a primer particularly created for 3D printed components, can be applied. It is critical to comply with the supplier's directions for the guide, including suggested drying times and also the variety of layers required. Sanding and polishing are likewise generally used to fine-tune the surface finish of SLS published components.Cable Separator Market to Hit US$ 408.13 Billion by 2033: Fact.MR Report - Yahoo Finance

Cable Separator Market to Hit US$ 408.13 Billion by 2033: Fact.MR Report.

Posted: Tue, 06 Jun 2023 16:00:00 GMT [source]

What Are Common 3d Printing Products?

It was this fact that brought 26-year-old Elzelinde van Doleweerd, a graduate in industrial layout from the Eindhoven University of Technology in the Netherlands, right https://s3.us-east-1.wasabisys.com/custom-printing/Customization-Trends/vehicle-wraps/br.html into the field. She began experimenting with bread, fruit and vegetables, the most frequently spoiled food in north Europe, to see if dehydrating them and also changing them into gorgeous shapes could give them a second life. This caused a six-month placement in 2021 in the test kitchen at the Copenhagen restaurant Alchemist, which is currently ranked 18th on the globe's 50 finest list.- " Every meaningful research study task requires lengthy reasoning and also preparation, as well as in the long run most concepts fail," he ends.

- The major disadvantages are limited materials which fuse but do not break down under the laser beam of light and the blog post handling required to get rid of trapped powder.

- Previously coated ceramic powders and also thermoplastics have actually been made use of in SLS.

- And also, on a lighter note, it's also possible to use edible materials, like delicious chocolate.

- Cells engineers have used 3DP to produce permeable ceramic scaffolds with completely adjoined channels straight from hydroxyapatite powder for bone substitute.

Social Links