November 7, 2023

Brand-new 3d Printing Strategy Ready To Progress Production

3d Printer Pointers And Techniques Xu et al. showed that inkjet printing innovation can precisely put the cells as well as proteins right into 3D alginate structures. The essential advantages are material flexibility as well as space temperature level handling. On top of that, a lot of the various other SFF modern technologies can not use all-natural polymers because of handling problems. One vital disadvantage is the trouble in making intricate shapes with overhangs since a momentary, sacrificial material is required. On top of that, Check over here hydrogels created in this technique have reduced stiffness which might lead to collapse of structures or restrictions on intricacy of forms.What are the 3D printing strategies?

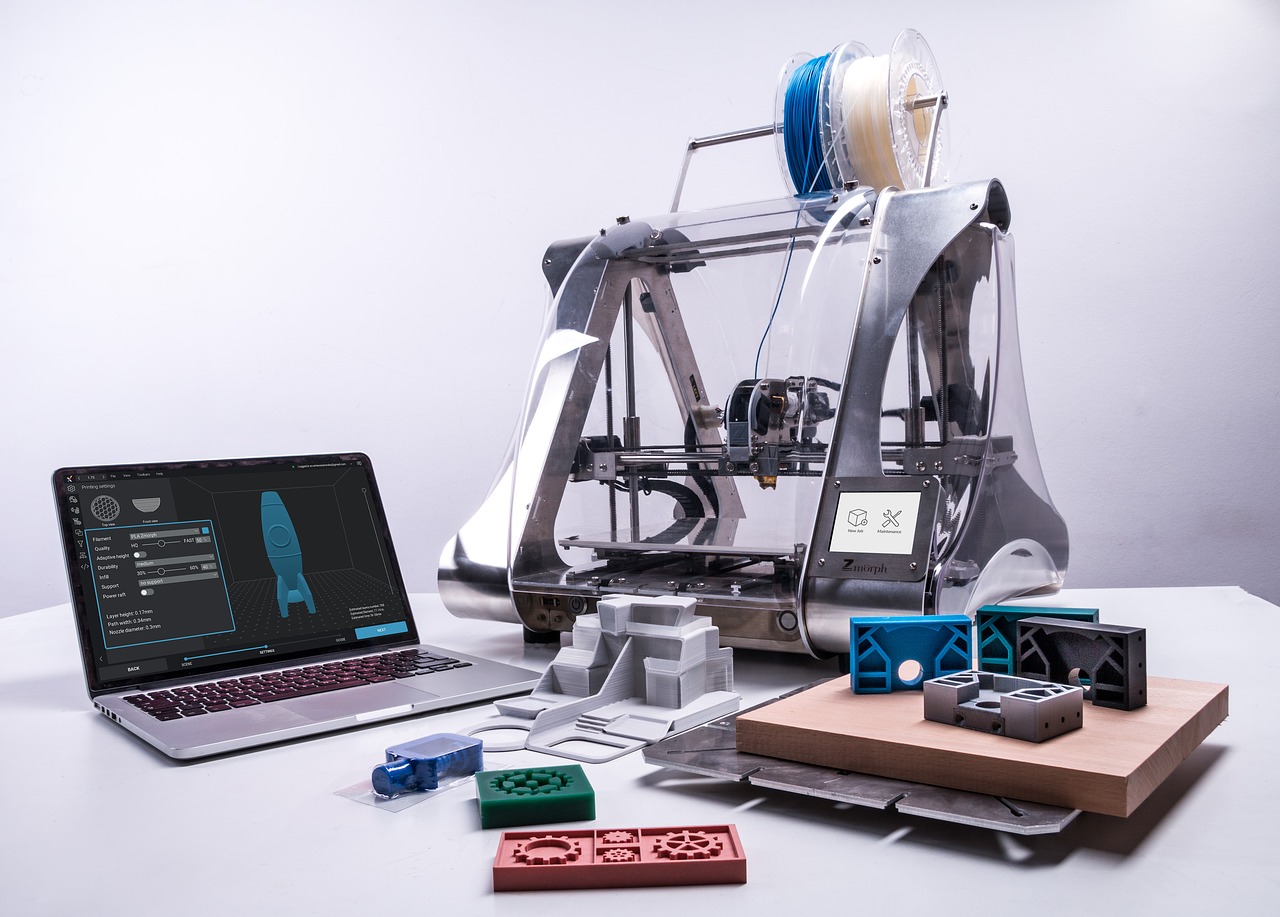

There are a number of sorts of 3D printing, which include: Stereolithography (SHANTY TOWN) Careful Laser Sintering (SLS) Merged Deposition Modeling (FDM).

First 3d Building Printing Meeting

You get a new print-- this time, you need it to be practical and cosmetically ended up. Your relied on 3D printing partner, Stratasys Direct Manufacturing, prints up your part in Molten Deposition Modeling, hand sands it down and also ships it back to you done in the span of five company days. Today, 3D publishing an early phase layout and re-printing it over night is practical as well as budget-friendly thanks to rapid prototyping or 3D printing systems like PolyJet and also Stereolithography. Where sustains are called for greatly relies on the material, develop procedure as well as build resolution, to name a few elements. Though it is most usual to 3D print plastics, as you'll see in our Full Overview to 3D printing materials, this is simply the start. According to the typically approved history of 3D printing, Charles Hull is the inventor of 3D printing. He carried out and patented the process of stereolithography 3D printing in 1986. Charles Hull likewise co-founded DTM Inc, later on called 3D systems, which is a world-leading 3D printing machine maker to this day.-- Product Extrusion

In some of their experiments, they have actually already ventured deep right into the nanoworld. Whether you're confused about which 3D printing method to use or you require fast prototyping solutions, RapidDirect is the suitable partner to have. If the resolution of components is among your key problems, after that the very best choice for you would certainly be to use SLA 3D printers. SLA generates much better and also extra thorough prints, permitting the construction of more accurate get rid of higher accuracy. The unique procedure repair services items which's where you'll typically see it regularly. As the solid item increases, the fluid resin is expected to fill out behind it, permitting smooth, continuous printing.Navy Must Go All In on Additive Manufacturing, Official Says - National Defense Magazine

Navy Must Go All In on Additive Manufacturing, Official Says.

Posted: Fri, 17 Mar 2023 07:00:00 GMT [source]

- The advantages of the modern technology are its fast mold and mildew fabrication, increased production performances, lowered labor, and digital removal of waste with material reuse for bespoke mold and mildews.

- The group is preparing to examine compounds such as lithium-iron or lithium-tin, and then to check how big the nano "fingers" on the electrode surfaces need to be, what spacing is possible, and how the electrodes ought to be lined up.

- Voxeljet prints molds for an aluminium sculpture of a new suburb in munich.

- Ultrasonic cleaning, on the other hand, makes use of high-frequency sound waves to produce tiny bubbles in a fluid bathroom.

Social Links