November 7, 2023

Brand-new 3d Printing Procedure Is Faster And A Lot More Accurate Than Conventional Approaches Sciencedaily

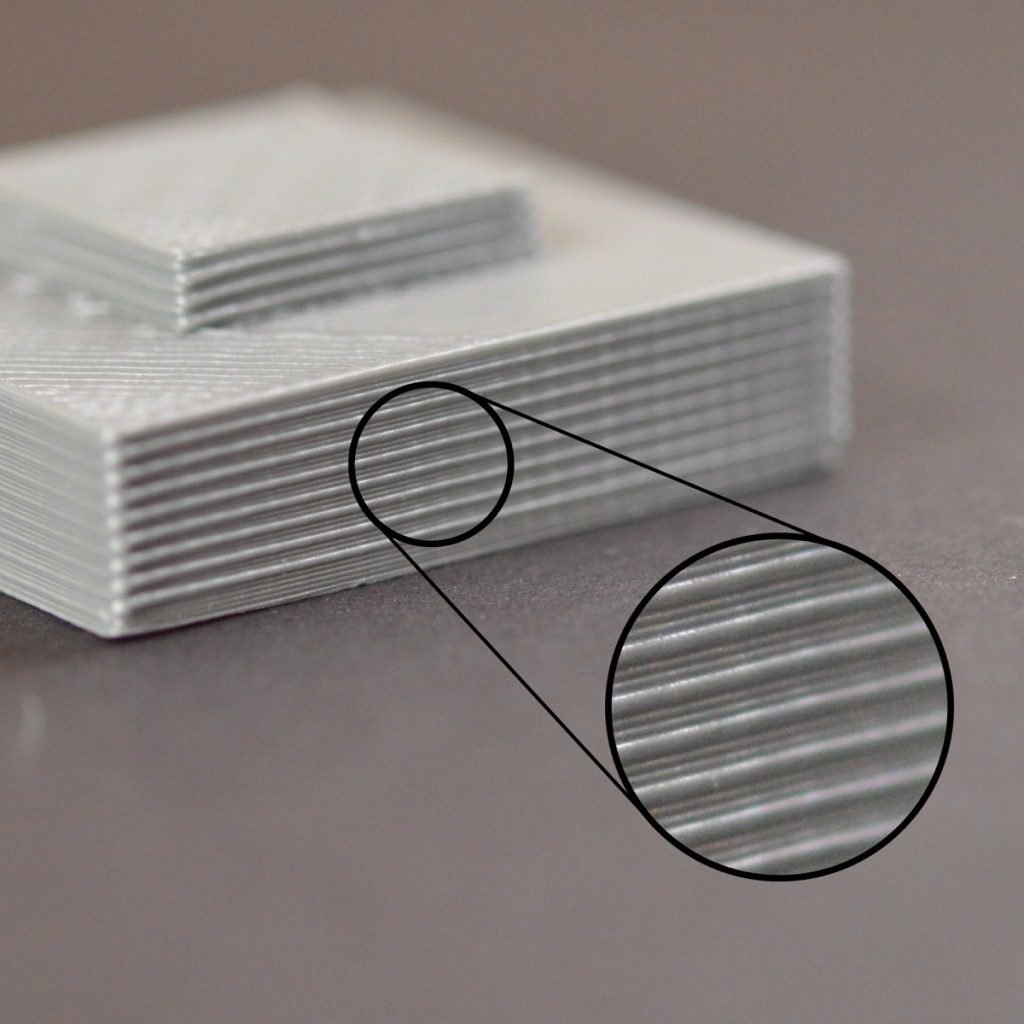

New 3d Printing Process Is Quicker And Extra Specific Than Conventional Techniques Sciencedaily In the pictures below, we have actually set out a few of the more wonderfully made complex layouts developed utilizing a 3D printing process called Laser Sintering. These 3D printed layouts are included, and also yet the component can be built in a combined system. With 3D printing, free-flowing, organic and also complex designs are flawlessly implemented while maintaining toughness in means impossible through any various other manufacturing process. A couple of prototypes later and you as well as your group arrive on it, the perfect model. The integration of SFF technologies with patient-specific medical imaging information makes it possible for the aseptic production of tissue engineering grafts that match exactly to an individual's shapes can be generated by. These technologies enable the manufacture of multi-functional scaffolds that meet the structural, mechanical, and nutritional needs based on optimized versions. Manufacture of intricate scaffolds such as interior networks or hanging attributes is conveniently attainable with this technique, given that objects are being sustained by bordering unbounded powders.What Are The Advantages Of 3d Printing?

" The chemical conversion of the material and all various other tests will certainly additionally need to be carried out inside the chamber," Momotenko describes. 3D printing is a wide term that consists of a collection of a number of different kinds of 3D printing as talked about earlier. Various other co-authors are from Sungkyunkwan College as well as Digital Light Innovations.Novel 3D Printing Method for Discovery, Manufacturing of New ... - Lab Manager Magazine

Novel 3D Printing Method for Discovery, Manufacturing of New ....

Posted: Wed, 31 May 2023 15:45:27 GMT [source]

Multi-material 3d Printing

Below are several of the areas where 3D print technique is playing an important part to drive development and development. Also after that, thermoplastics are amongst one of the most popular products for 3D printing technologies today. Acrylonitrile Butadiene Styrene, Polylactic Acid, PolyCarbonate, and also Polyvinyl Alcohol are a few of one of the most common options throughout different sectors as a result of their convenience and also appropriate qualities.What are the 3D printing methods?

There are a number of types of 3D printing, that include: Stereolithography (SLA) Selective Laser Sintering (SLS) Merged Deposition Modeling (FDM).

- In 2019, a little over half of respondents stated that they were making use of machining; currently, virtually three-quarters of participant are, uncrowning polishing as the most preferred alternative.

- Since 2021, the clay-mixture home Tecla can be published in 200 hours, while the blend may take weeks to dry.

- Grinding, on the various other hand, is used to achieve ultra-fine surface area finishes and high-precision geometries, such as those needed for securing surface areas or bearing elements.

- The choice of rough products, brightening rates, and also used pressures can significantly affect the final surface finish and also must be very carefully managed to accomplish the wanted result.

Social Links