January 18, 2024

Does Reducing Print Rate Boost High Quality? Affecting Variables!

Just How Advanced Printing Technology Decreases Printing Prices This adjustment will translate into less activity and wobble for your printer which will create far better quality 3D prints. This might be triggered by irregular extrusion when print rate is altering according to your setups. Some individuals like to have different rates throughout different sections of the print, but I figured out that keeping a general constant rate throughout printing supplies the most effective print high quality. Printing also low, or with way too much flow price can additionally make your prints stick too well on your construct plate potentially harmful your print surface area.- The manufacturing industry is constantly on the quest for new modern technologies to help them grow.

- 3d printing technology is highly cost-effective and extremely beneficial for startups & small businesses as it permits them to produce things on demand.

- For this reason you will not get the top quality result by those heat subjected inks.

- Experiment with these 3 settings till you discover a great value for your printer.

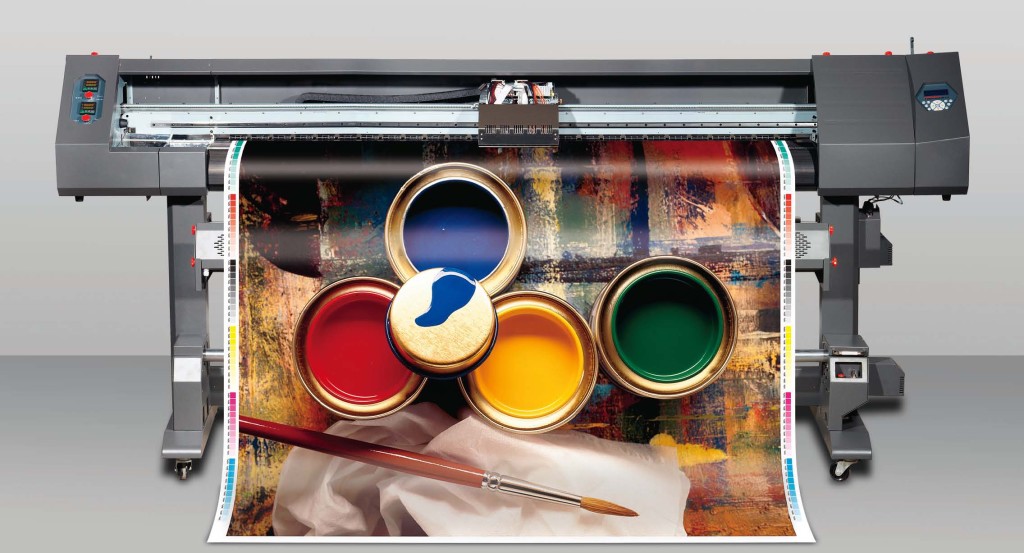

Broadband Ink Jet Customization

Please bear in mind that this is a firmware feature that needs to be made it possible for in your firmware, and you must just do it after you have actually called in your various other printing specifications. Constantly orient your version with the highest overhang dealing with the part cooling down follower duct, to get one of the most reliable cooling. But first, get a retraction worth that works, then begin tweaking. I always tighten up the belts just sufficient so they don't slip from the motor sheaves and the belt is extended. Some people do all kind of dimensions on the audio frequency made by the belts, yet I constantly had acceptable results with straightforward tightening up.How Metrology Ensures Quality in 3D Printing - AZoM

How Metrology Ensures Quality in 3D Printing.

Posted: Wed, 23 Aug 2023 07:00:00 GMT [source]

How Innovative Printing Modern Technology Lowers Printing Prices

The temperature level reported by the thermistor from a printer's hotend is not as accurate as you might anticipate. Sometimes, the real temperature inside the heatblock can vary between 10C to 15C from the one reported by the thermistor. Besides that, utilizing nozzles with different materials can influence the temperature level you require to use for some filaments. Very first layer lines need to touch each other, and there must be no space between them. If your initial layer flow rate is expensive, too much filament will certainly be extruder and the published lines will be lower in the middle, and greater on the sides creating a recognizable pattern. Various nozzle temperatures can likewise have a various finish for the same filament. For example, in the image below you can see how making use of a reduced temperature can generate a matte finish and a higher temperature level can generate a shinier print. Some filaments can have moisture even if it's brand new and opened up fresh, so make sure you take a look at my article on Just how to Dry Your Filament. We recommend using the manufacturer-recommended slicers for the very best results. Advanced slicing programs think about GD&T, which produces parts with functionality intent parameters. Do not put your printer near devices like CPU, monitor, and others that produce warm constantly. If you have any concerns relating to any one of our product and services, please do not hesitate to contact us.Social Links