November 7, 2023

Print Troubleshooting Photographic Overview

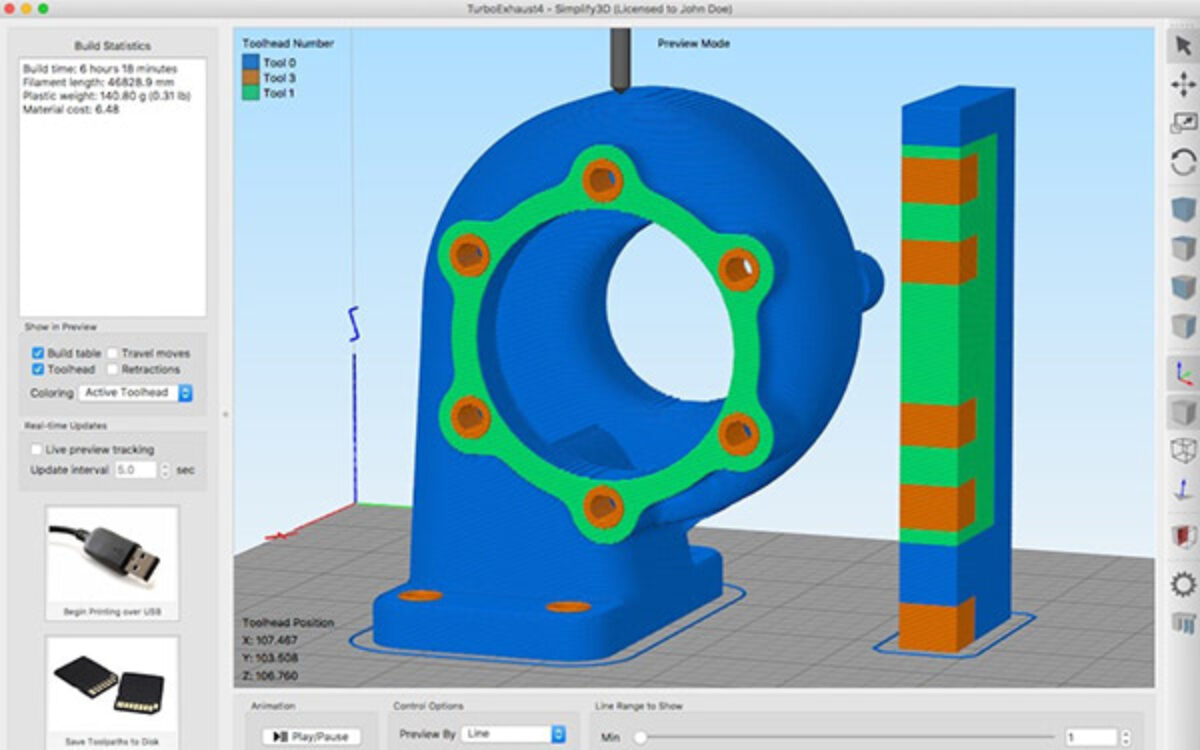

3d Printing Troubleshooting Overview You can begin with the temperature level recommended by the filament firm, then boost it by ten levels to see what occurs. Such issues with 3D printing frequently take place when you are switching from abdominal muscle to PLA regularly. It is best to do this when you heat the nozzle to the proper temperature level utilizing your computer software application. The filament you were previously printing, printed at an extremely various temperature level to the current filament. If the trouble is brought on by too many retractions, use a slicer software application that permits far better control and decrease the amount of retractions taking place. Usage good calipers or an even better a micrometer screw scale to gauge the size of the filament resulting the spindle as well as examine if it is round or has actually been flattened. If it is thicker than it needs to be or no more perfectly rounded, return the spool to the manufacturer/seller for a substitute. Affordable filaments often have big fluctuations in their size.How To Fix Component Of The Print/supports Shifted Or Apart Entirely

If both of Browse this site the sides went through matching, it's time to buy another glass. The design you have actually just printed. needs to cool completely before ending up being very easy to remove. Sometimes, the design might be separated automatically after some cooling. Air conditioning of the filament provides its solidification and loses it sticky top qualities that were required for layer bonding. Furthermore, every published design with huge lower area can stick to the system fairly strongly. For this, you need to improve the speed of the extrusion fan in order to provide enough cooling.What are the usual 3D printing troubleshooting troubles?

- Not Squeezing out at Beginning of Print. Printer does not extrude plastic at the beginning of the print.Not Sticking to the Bed.Under-Extrusion. Over-Extrusion.

- Gaps in Top Layers.Stringing or Oozing.Overheating.Layer Shifting. Size.

- One function to consider when

- producing your item is it's scale.The resolution.

- Throughout additive production, the resolution refers to the density of each layer of product being'applied.Wall thickness.The orientation.The choice of

- material.Design balance. When a PLA filament absorbs wetness, it inflates, raising the danger of extruder jams. Moisture also triggers PLA to produce prints with bubbles and also gaps externally, for that reason spoiling your prints

- .

Recap Of Solutions: Leading Layer Of The Model Has Bumps, Fractures And Also Voids (pillowing)

This can be a little bit challenging initially, yet it's vital for making certain that your prints come out appropriately. Ensure to follow the guidelines meticulously and also utilize a piece of paper or other slim material to evaluate the void in between the build plate as well as the display. The overview was created with all degrees of 3D printing know-how in mind.- Generally, the couplers are located in certain areas given that they are attached to a stepper electric motor as well as to a particular pole that regulates the print head.

- The print bed is normally by hand leveled, or if fortunate, your printer might have a vehicle bed leveling function.

- Today's option is the substantial Articulated Dragon by Cults contributor MCGYBEER and published to range by Metalhead Printing.

- A misaligned printer framework or bed will certainly cause a leaning print too, check whatever is as straight as feasible.

- Little attributes can make or break an elaborate design, so it's a major concern in regards to 3D print quality troubleshooting.

Mistake Of Surfaces

Additionally, reduce the temperature when the printer is coming close to the problem area. If you're not making use of 100% component cooling fans you can try boosting up to 100% which needs to assist. This might not appropriate for all filaments though so make certain to check the producers referrals. If printing several parts simultaneously, attempt printing solitary objects rather than placing multiple things on the construct plate. This eliminates all travel moves between several things and will certainly cut down on 3D printing stringing & oozing between several prints.12 Troubleshooting Tips for 3D Filament Prints Gone Awry - Online Tech Tips

12 Troubleshooting Tips for 3D Filament Prints Gone Awry.

Posted: Sat, 07 May 2022 07:00:00 GMT [source]

Social Links