November 7, 2023

3d Printing Troubleshooting: All Problems & Solutions

New Overview Makes It Simple For Any Person To Enhance Their 3d Print Quality Software Talk Manufacturing If you prepare to link designs that were printed independently see to it that the inserts are a little smaller sized than the port they require to go into. If you're producing a model that features openings, ports or other information that need exact dimensioning, it would be a shame if even one of them appeared incorrect. This is exactly what takes place if your version shed its dimensional accuracy. Several of the parts will not line up as well as fit and it will be tough or impossible to correctly put together the end product you have actually wanted to develop. Additionally, you can boost the cooling of the print making use of fans to make sure that the filament dries faster and there's a lower chance of balls creating as a result of thaw product. This can be done making use of far better fan ducts or updating your cooling followers completely. Adjusting your e-steps or extruder steps is a helpful technique that customers have used to take care of balls & zits on their design. If your printer is not squeezing out sufficient plastic to fill the distance in between nozzle and also bed, you will certainly wind up with bond issues. Way too much, or over-extrusion as well as you have excess filament that requires to go someplace. The initial way to repair this problem is to ensure the system is level.Jammed Nozzle/ Stopped Up Extruder

If none of the above solutions work for you, you can try utilizing a 2.85 mm diameter filament. This is an odd issue that is only discovered near the end of the print. There seem holes or voids between nearby layers on the top surface area. While the remainder of the print will be remarkable, the leading layer will trigger the print to fall short.3D Printing News Briefs, March 2, 2023: Micro 3D Printer & In-Situ Inspection & More - 3DPrint.com

3D Printing News Briefs, March 2, 2023: Micro 3D Printer & In-Situ Inspection & More.

Posted: Thu, 02 Mar 2023 08:00:00 GMT [source]

Finest Dnd Stl Data: Minis And Also Figures To 3d Print From Dungeons And Also Dragons (Cost-free & Not)

Place the affixed print and also bed right into a freezer for a few hours. The print needs to then stand out off with some light tapping when awesome enough. Some materials are understood for sticking exceptionally well to the bed, check maker info for information.- So, offer it the attention it is entitled to and print infill like an integral component of the model.

- Issue Common Cause Modification Forum Link If you are not particular concerning having properly adjusted your printer, confirm that it is calibrated initially as that is the first step.

- But when it involves publishing a fine detail, the final product has a lot of misprints.

- Turn the printer on - Some mainboards will come to life exclusively from a 5V USB cable, where as others need the primary power button switched on.

Electric Motor Is Wildly Reversing And Also Forth Despite No Filament Packed:

Some of their guidance specifies to their software, as they want to ensure their users are successful with 3D printing. Simply boosting your retraction setups for your particular 3D printer arrangement can repair this concern. The default setups in Cura of 5mm retraction distance and 45mm/s retraction rate functions well for a Bowden tube arrangement. Because warping normally takes place in the very first few layers of your model, having a correctly leveled bed is a good way to deal with warping because it provides much better adhesion. Having a 3D printer that isn't appropriately leveled makes warping more likely to occur. Similar to rapid cooling of the filament, minimizing the drafts or gusts of air in your printing setting can aid to decrease bending or curling in your models. I would certainly recommend taking the PTFE tube out and also having a correct look at https://sgp1.vultrobjects.com/large-format-printing-services/Graphic-Software/design-inspiration/the-ultimate-guide-to-the-most-effective-pla.html it. After looking at it, you may simply need to clean out a clog, or replace the PTFE tube entirely if it's harmed. Below is a picture of Boating in Cura on an XYZ Calibration Cube. You can choose a Raft just by entering into Cura, scrolling to Build Plate Bond in the settings food selection, after that selecting Boating, exact same with a Brim. Keeping your printer in great working order goes a long way in getting the very best results possible.What are the typical 3D printing troubleshooting issues?

- Not Squeezing out at Beginning of Publish. Printer does not squeeze out plastic at the beginning of the print.Not Staying with the Bed.Under-Extrusion. Over-Extrusion.

- Voids in Top Layers.Stringing or Oozing.Overheating.Layer Shifting. Size.

- One feature to think about when

- creating your item is it's scale.The resolution.

- During additive manufacturing, the resolution describes the thickness of each layer of material being'applied.Wall thickness.The orientation.The selection of

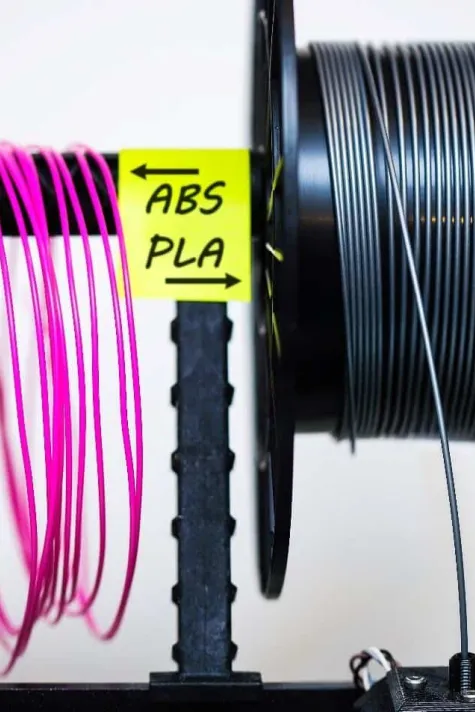

- material.Design equilibrium. When a PLA filament soaks up moisture, it inflates, raising the danger of extruder jams. Wetness likewise triggers PLA to produce prints with bubbles and also gaps externally, therefore wrecking your prints

- .

Social Links