November 7, 2023

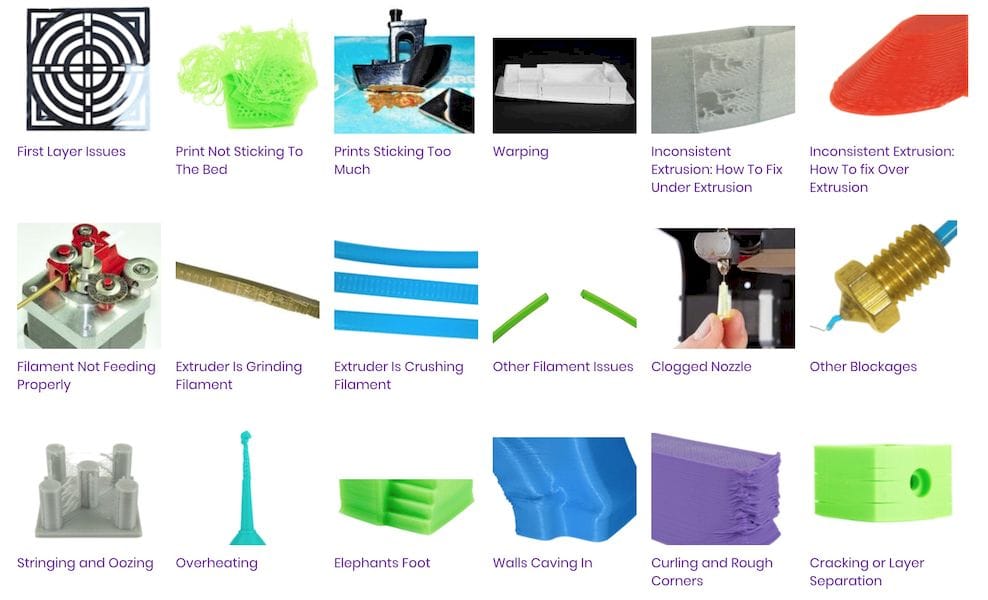

3d Printing Troubleshooting: All Troubles & Solutions

3d Printing Troubleshooting: All Troubles & Remedies The process of bed leveling varies from printer to printer. Some utilize an automatic system, the others overviews you with actions. Have a look at your device's guidebook to figure out exactly how you can most likely change the bed. To boost the probability of the filament bonding to the print platform, you will need to add some product for a structure. Generally it means applying a layer of a stick adhesive that is very easy to wash.How do you know if PLA filament is bad?

Your Print Doesn't Stick To The Bed

There is a noticeable scrape on the top layer that is not a line from oozing filament. Minimizing the infill overlap quantity in your slicer will likewise help. Curling and also rough corners is extremely simple to spot and looks rather the mess contrasted to the sides of the print. The weight of the subsequent layers squashes the reduced layers that never ever had a possibility to fully set.- You currently attempted [Under extrusion happens when your printer is unable to provide the appropriate amount of material required to correctly print a layer.

- Manufacturing of great information is executed with slow-moving printing speed and also it's also recommended to reduce the fan rate in order to adapt to the rise in extrusion time.

- Printing also hot will create the filament to be too runny as well as also mean it will certainly take longer to cool down as soon as published permitting stringing and also oozing.

- Numerous common 3D printing issues originate from a poor initial layer.

- If you feed this product right into your system, no adjustments will change anything incorrect.

Indications Of Flawed Infill:

The printer can also be connected to a computer system, so you can heat the nozzle making use of the host program. Use a tiny pin as well as clear the hole once the material reaches this temperature. Bed temperature - The bed temperature and nozzle temperature ought to match those stipulated by the filament maker. The infill synopsis overlap is also little-- all slicers can establish how much the infill overlaps the outlines/perimeters of the item being printed. This setup makes sure they go all the way to the side and also fuse together and so aid sustain the layers over. We will certainly cover the troubles that might take place to the printers using the FDM and also shanty town innovations, including assistance failure as well as imperfect bond and several others. The factor for the inclusion of the shanty town problems is the climbing quantity of budget friendly desktop options that utilize this innovation. One, otherwise the most common trouble we see in technology support is people printing way too hot. Appropriate temperature is among the primary conditions that decides whether the material will establish or otherwise. If the system you utilize can be taken into consideration an old one, the solution you search for is that the system ends up being over-textured with layers of glue. This concern is usually paired with cracks in the glass that obtain filled with the filament and serve as some kind of roots. In fact, there are print systems that contain holes as a part of their style, so the prints tend to be challenging to detach. In general, the couplers lie in details locations given that they are attached to a stepper electric motor and also to a particular pole that manages the print head.3D Printing News Unpeeled: 316L Qualified for the Navy, Markforged & Continuous Lawsuit, Teddy Bears - 3DPrint.com

3D Printing News Unpeeled: 316L Qualified for the Navy, Markforged & Continuous Lawsuit, Teddy Bears.

Posted: Thu, 06 Apr 2023 13:42:31 GMT [source]

Social Links