November 22, 2023

Anycubic Photon Material 3d Printer: Ideas, Methods, And Repairing Overview

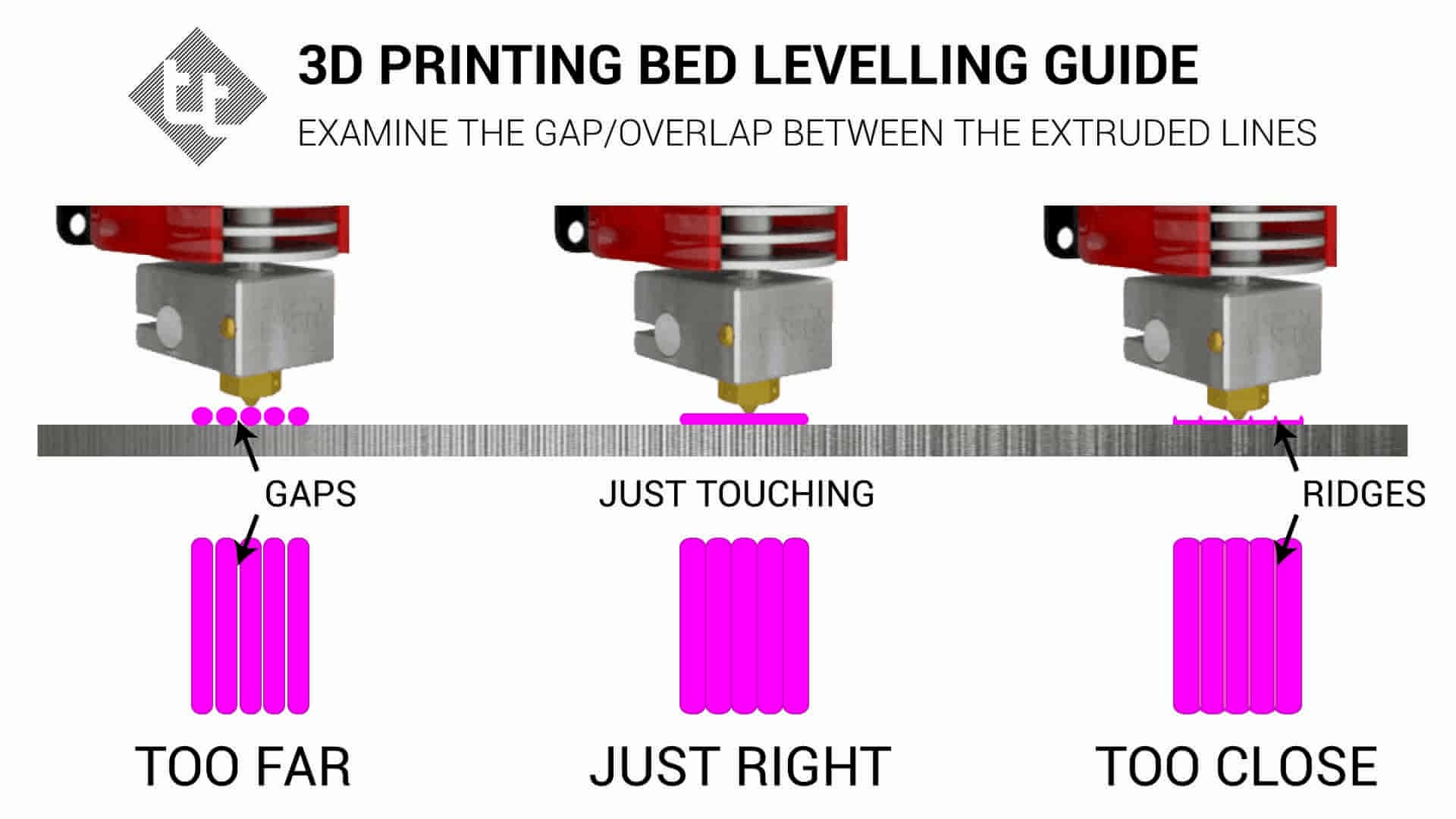

3d Printing Troubleshooting: All Problems & Services In many cases, the trouble shows up because of wrong alignment of the print, meaning that it will not have the ability to hold up against the peel stamina. This will certainly create the activity distortion which in its turn leaves you with another problem-- the successive layers will be created on the barrel interface as opposed to print itself. This may be difficult, yet you are actually able to create some openings on the print base and evade all the circumstances where sticking is brought on by excess surface area contact as well as suction. You completed the printing and also the model looks lovely, but there still is a trouble. One more important reason for the issue is that the filament isn't cooled down quick enough as well as is not able to support itself over a void. The fastest and most obvious solution would certainly be to just get rid of the strings on your own.What are the usual 3D printing troubleshooting issues?

- Not Extruding at Beginning of Print. Printer does not extrude plastic at the start of the print.Not Sticking to the Bed.Under-Extrusion. Over-Extrusion.

- Voids in Leading Layers.Stringing or Oozing.Overheating.Layer Shifting. Size.

- One feature to take into consideration when

- producing your product is it's scale.The resolution.

- Throughout additive manufacturing, the resolution describes the thickness of each layer of product being'applied.Wall thickness.The orientation.The choice of

- material.Design balance. When a PLA filament soaks up dampness, it swells up, increasing the danger of extruder jams. Wetness also triggers PLA to create prints with bubbles and also spaces on the surface, therefore ruining your prints

- .

Smoke Coming Out Of Your Nozzle

NinjaFlex ® specifically must have a smooth, glossy surface. This mistake is generally seen on the sides yet can be on a leading surface periodically. You're seeing heaps or swellings of spare/oozed filament deposited on the outer surfaces of a print. You're seeing one area of a print that looks poor or distinctive, while other surfaces of the ended up print are tidy and also well-formed. If you're seeing drips or scars caused by the nozzle overlooking a currently completed section of the print, you could be over squeezing out. You're seeing the print beginning to peel off up from the print surface at edges, or slim sections snuggle during printing.- When it comes to SLA printing modern technology, a photopolymer material needs to be set through a UV-light source - a laser, generally.

- Make certain you're not pushing down on your bed when levelling it.

- You may likewise just continue relocating your prints until there disappears areas suitable for printing.

- Degrease your bed surface area consistently according to the maker's Include an extremely thin layer of talcum or baby powder onto your bed.

Exactly How To Take Care Of Gaps Between Infill And Also Outer Wall Surface

No filament deposition in spite of it being packed as well as the print head continuing to move customarily. Regardless, particularly if your printer's extrusion system is of a Bowden design, you will require to extract the filament as well as feed in the new one. The printer outright declines to produce the print, no filament is squeezed out from a nozzle. With the proper specifications, you can override the firmware and manually turn on connected equipment. With the appropriate gcode, I took care of to switch on the MOSFET for the hot end which swiftly started to elevate the temperature level without any target, thus the warning additionally up this web page. I couldn't locate a means to exit this viewing state without resetting the printer.2023 3D Printing Predictions: 3D Printing in Healthcare - 3DPrint.com

2023 3D Printing Predictions: 3D Printing in Healthcare.

Posted: Tue, 27 Dec 2022 08:00:00 GMT [source]

Holes And Pits In Leading Layer

When publishing also quickly, the equipment concentrates extra on finishing the work than doing it right. The motor may try to send the head to the settings you input, however it can not stay on top of speed too expensive. You can lower the rate by 50% at the same time setups tab to see if this is the cause. When this happens, people call the filament "removed" since there isn't sufficient 3D printing product left for the extruder to take into your print. You'll recognize the issue instantly because you can listen to the equipment grinding and also see small plastic shavings around the print bed. Seeing gaps in layers is frustrating to make sure that this pointer will certainly assist with 3D print high quality troubleshooting.Social Links