November 22, 2023

3d Printer Fixing Overview

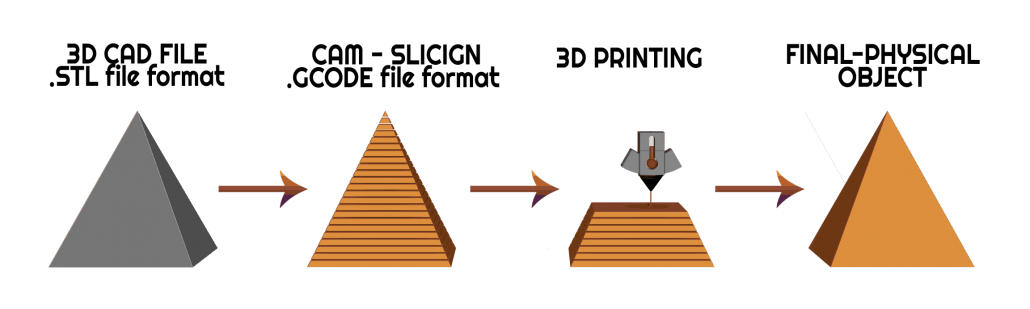

Troubleshooting & Materials 3d Printing Additive Manufacturing Sbu Libraries At Southwest Baptist University Libraries Attempt raising this and note the outcome (too much and also you will likely see the infill pattern jabbing with the object's visible wall surfaces as well as other such surface areas). If your slicer sustains it, established a minimal time per layer to make sure proper cooling. This usually results in the slicer dynamically decreasing the print rate to make sure the minimum layer time, which, in this particular instance, won't aid all that much. Particularly when changing to smaller nozzle dimensions your extrusion settings require to be place on. The smaller size holes are way much less forgiving as we're dealing with greater pressure attempting to extrude via a smaller hole to start with. If you attempted to insert a new filament since your 3D printing project would not begin, and also nothing works, you could be dealing with a blocked nozzle problem. A listing of usual 3D printing issues is not recognized to all enthusiasts with a 3D printer in the house. Some enthusiasts are fortunate to experience no issues with their devices. Nevertheless, this strip of luck can unexpectedly break for no evident factor.Nozzle As Well Far From The Print Bed

Then transform a small, handheld fan on it to help it cool off and completely dry in the right area. Your 3D printer sets one layer at once, yet lots of designs have details guidelines for each and every layer to guarantee it integrates in the optimal finished product. A trouble with one layer can shake off the whole print, so you intend to take care of any issues with splitting as well as splitting up. Initially, the filaments won't thaw sufficient to mold and mildew with each other correctly. You require to set the print temperature high sufficient to deliver a high quality print. You might observe that your print starts fine however obtains off-course when you develop big and also intricate projects.- Each 3D printing product has its own optimum printing temperature, and also each printer is different.

- Check with the filament supplier's documentation to see to it.

- A too much countered could produce the problem of the designs not staying with the bed.

- This takes place primarily with items with a large surface area in the initial layers.

Printer Particular Suggestions

You may either get filament that partly congests the PTFE tube area or you can experience warmth damages at the part of television near the hotend. You can raise the printing temperature in 5-10 ° C increments to see exactly how that functions. Have a look at the suggested printing temperature of your filament by considering the details on box that it came in. Examine the advised bed temperature level for your filament, then attempt using the higher end of it.What are the common 3D printing troubleshooting problems?

- Not Extruding at Begin of Publish. Printer does not squeeze out plastic at the beginning of the print.Not Staying with the Bed.Under-Extrusion. Over-Extrusion.

- Voids in Leading Layers.Stringing or Oozing.Overheating.Layer Shifting. Dimension.

- One attribute to take into consideration when

- developing your item is it's scale.The resolution.

- Throughout additive production, the resolution describes the thickness of each layer of product being'applied.Wall thickness.The orientation.The choice of

- material.Design balance. When a PLA filament soaks up moisture, it inflates, enhancing the threat of extruder jams. Moisture also creates PLA to produce prints with bubbles as well as spaces on the surface, therefore wrecking your prints

- .

3D Printing Bureau Fast Radius Acquired by SyBridge Technologies For $15.9M - 3DPrint.com

3D Printing Bureau Fast Radius Acquired by SyBridge Technologies For $15.9M.

Posted: Mon, 12 Dec 2022 08:00:00 GMT [source]

Social Links