Essential Safety Precautions Before Beginning Work

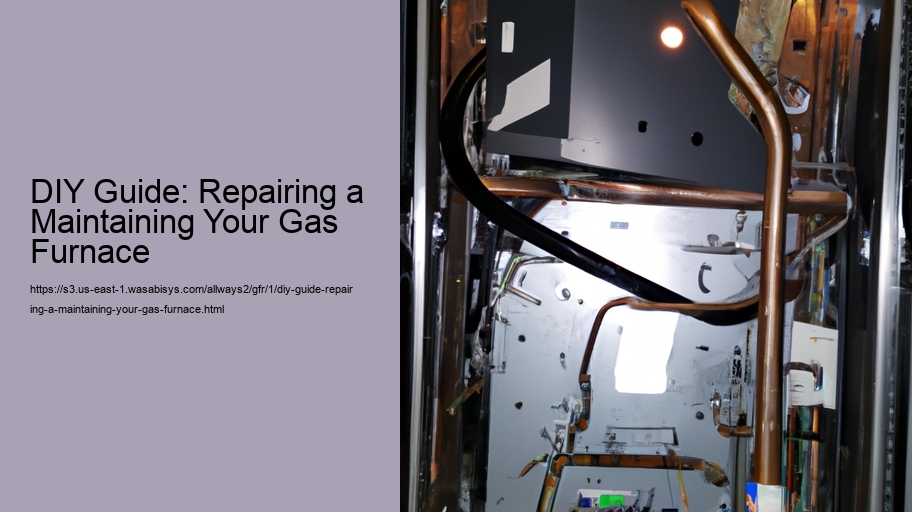

Embarking on the journey of repairing and maintaining your gas furnace can be a rewarding experience, saving you both time and money. Get in contact with All-Ways Heating & A/C for professional gas furnace repair you can count on in the Snohomish County area. boiler repair However, safety should always be your primary concern when dealing with any DIY task, especially one that involves natural gas and electrical components. Below are essential safety precautions to consider before beginning work on your gas furnace.

Firstly, ensure that you have read and understood the manufacturer’s manual for your specific model of gas furnace. The manual contains critical information about the parts, operation, and maintenance guidelines specific to your unit. Ignoring these instructions can lead to improper handling and potentially hazardous situations.

Before starting any repairs or maintenance tasks, turn off the power supply to the furnace. This is typically done at a service switch near the unit or at the main circuit breaker panel in your home. It is crucial to do this to prevent any electrical accidents while working on the furnace.

Similarly important is shutting off the gas supply to avoid leaks and potential fire hazards. Locate the gas valve near your furnace—it usually has a lever that you will turn perpendicular to its pipe—which signifies that it's closed—and thus safely shuts off the flow of gas to the unit.

Wear appropriate protective gear while working on your furnace. Durable gloves protect against cuts from sharp metal edges within the unit while eye protection guards against dust particles or other debris that could cause injury.

Make sure you have adequate ventilation in the area where you're working. Gas furnaces produce carbon monoxide (CO) when running; if there's a leak or if combustion byproducts cannot vent properly due to blockage in flue pipes or vents, CO levels could become dangerously high.

Invest in a quality carbon monoxide detector for an added layer of safety; it will alert you if CO levels rise above safe limits—a vital tool since carbon monoxide is odorless and colorless, making it impossible to detect without assistance from such devices.

Familiarize yourself with all emergency procedures related to your heating system as well as local emergency contact numbers in case something goes wrong during maintenance activities which require professional intervention immediately.

It’s also wise not undertake repairs beyond what you’re comfortable with handling—gas furnaces involve complex systems where mistakes can have serious consequences. If at any point during troubleshooting or repair processes things seem out of depth for your skill set, do not hesitate calling qualified HVAC professionals who are trained handle sensitive components safely efficiently.

Lastly but importantly: never ignore smells indicating leaking gas (rotten eggs smell), sounds suggesting malfunctions (screeching bearings), visual signs like sooty marks around vents — these may indicate deeper issues requiring immediate expert attention rather than DIY fixes.

In conclusion, by following these essential safety precautions before diving into repairing and maintaining your gas furnace yourself can help prevent accidents ensure successful outcomes every step way – remember respect complexity inherent within these powerful household appliances prioritize wellbeing above all else during DIY endeavors!

Tools and Materials Needed for Gas Furnace Repair

Repairing and maintaining your gas furnace is a critical task that ensures the warmth and safety of your home during the cold months.

DIY Guide: Repairing a Maintaining Your Gas Furnace - furnace troubleshooting

- circuit board troubleshooting

- chimney inspection

To prepare for a variety of common repairs or maintenance tasks on your gas furnace, here's an essay discussing the essential tools and materials you might need:

**Basic Hand Tools**

A set of basic hand tools is indispensable for most furnace repair tasks. This includes screwdrivers (both flat-head and Phillips), adjustable wrenches, pliers, and a socket set. These tools will help in opening panels, tightening connections, replacing parts like sensors or igniters, and performing general adjustments.

**Multimeter**

A multimeter is an electronic measuring instrument that combines several measurement functions in one unit. It can measure voltage, current, resistance which are all important when dealing with electrical components of a gas furnace. A multimeter will help diagnose issues such as faulty wiring or malfunctioning electronic controls.

**Leak Detection Solution**

If you suspect a gas leak in any part of the heating system, a leak detection solution can be applied to pipe fittings and connections to identify leaks by forming bubbles at leak points. It's important to address these immediately due to the explosive nature of natural gas.

**Igniter**

Over time, the igniter in a gas furnace may fail. Having a replacement ready is smart so you can promptly substitute it if there are signs of wear or failure after testing it with your multimeter.

**Thermocouple**

The thermocouple serves as a safety device that shuts off the gas if the pilot light goes out. If troubleshooting leads to this component being faulty – having one on hand could save you time during repair.

**Capacitor**

Should your blower motor not start up properly or exhibit unusual behavior like humming without turning; it might be due to a bad capacitor which often requires replacement.

**Filter**

A simple yet crucial aspect of maintaining your gas furnace involves regularly changing its air filter. furnace filter upgrade This keeps air quality high while ensuring efficient operation by preventing dust build-up within internal components.

**Furnace Tape**

Metallic tape specially designed for furnaces can withstand high temperatures and should be used when sealing any ductwork gaps or making minor repairs where heat resistance is required.

**Safety Gear**

Safety should never be overlooked when repairing appliances that involve electricity or natural gases. Make sure you have safety glasses to protect your eyes from debris, heavy-duty gloves to protect from sharp metal edges inside the unit, and perhaps even a respirator if dust or insulation fibers are present.

Remember that while many tasks associated with maintaining a gas furnace could potentially fall into DIY territory—such as changing filters or cleaning sensors—other more complex issues involving gas lines or electrical components may best be left to professionals due not only to complexity but also because they pose significant safety risks if mishandled.

Before starting any repair work on your own ensure local regulations allow homeowners to do so without professional certification—and always disconnect power before beginning work on any appliance! Your first priority in DIY projects should always be personal safety followed closely by preserving proper functionality of vital home systems like heating units through careful attention using appropriate tools & materials.

Routine Maintenance Steps for Keeping Your Gas Furnace Running Smoothly

Maintaining your gas furnace is essential for ensuring it runs smoothly, efficiently, and safely throughout the cold season. Regular routine maintenance can prevent unexpected breakdowns, extend the life of your furnace, and keep your heating bills in check. Here's a short essay on the routine maintenance steps you should follow to keep your gas furnace in tip-top shape.

Firstly, always prioritize safety before performing any maintenance on your gas furnace. Ensure that the power to the furnace is turned off at the breaker box to avoid any electrical hazards.

DIY Guide: Repairing a Maintaining Your Gas Furnace - furnace filter upgrade

- gas leak detection

- boiler repair

One of the simplest yet most crucial steps in maintaining a gas furnace is regularly changing or cleaning its air filter. A clogged or dirty filter restricts airflow, forcing your furnace to work harder than necessary. This not only increases your energy bills but can also lead to premature wear and tear on the unit’s components. Check your filter monthly during peak usage times and replace or clean it as needed.

Next, inspecting and cleaning the blower assembly is important for maintaining efficient operation. Dust and debris can accumulate around the blower wheels and motor, which impedes performance. Carefully remove these elements using a vacuum with a soft brush attachment; this will ensure optimal airflow is maintained within the system.

The heat exchanger should be inspected for signs of corrosion or damage annually by a professional since a compromised heat exchanger can lead to dangerous carbon monoxide leaks into your home.

It's also beneficial to check on all electrical connections within your furnace system periodically. Loose connections can cause improper operation or even pose significant safety risks due to potential fires. Tighten any loose wires and connectors if necessary, but if you're unsure about handling electrical components, it’s best left to professionals.

For high-efficiency furnaces with condensation drains, make sure those drains are clear of obstructions so that moisture can exit properly from the system without causing water damage or affecting performance.

Another key component of routine maintenance is checking that all venting systems remain unblocked. Your exhaust flue must be clear of obstruction so harmful gases are vented out safely away from indoor living spaces.

Finally, regular professional inspections are indispensable despite how much routine DIY care you provide for your furnace. An experienced technician has specialized knowledge and tools required for more complex checks like ensuring proper burner combustion and testing safety controls within the system.

To sum up, keeping up with routine maintenance such as replacing filters regularly; cleaning blowers; inspecting heat exchangers; checking electrical connections; ensuring condensate drains are clear; making sure vents are unblocked; plus scheduling professional inspections all contribute significantly towards keeping a gas furnace running smoothly – enhancing efficiency while prioritizing household safety above everything else.

Troubleshooting Common Issues with Gas Furnaces

When it comes to maintaining warmth and comfort in our homes during the cold months, gas furnaces are among the most common appliances relied upon. They're efficient, effective, and usually run without a hitch. However, like any piece of machinery, they can develop issues that may require troubleshooting and repair. This short essay will serve as a DIY guide for repairing and maintaining your gas furnace to ensure it continues to function correctly.

Firstly, safety is paramount when dealing with gas appliances. Before attempting any repairs or maintenance on your gas furnace, ensure that you have turned off the power supply and the gas valve to prevent accidents.

One of the most frequent problems homeowners face with their gas furnaces is a failure to produce heat. If this occurs, start by checking the thermostat settings; it's possible that it was accidentally set too low or switched off. If the thermostat isn't the issue, inspect your circuit breakers or fuse box—there could be a tripped breaker or blown fuse.

Another common issue is inadequate heating performance where the furnace runs but doesn’t generate enough heat. This problem may stem from dirty filters obstructing airflow. Regularly replacing or cleaning air filters can prevent this issue and also help extend your furnace’s lifespan.

If your furnace starts and stops frequently—a condition known as short cycling—it might indicate an overheating problem caused by restricted airflow due to clogged filters or a malfunctioning blower motor. Checking these components should be part of your regular maintenance routine.

Strange noises coming from your furnace can also be alarming: rattling suggests loose panels which need tightening; whining could point towards bearing issues in the inducer motor or blower; while banging noises might indicate delayed ignition due to dirty burners.

In instances where there is no ignition in pilot-equipped units, you could be facing a faulty thermocouple that needs replacement or simply a pilot light that has gone out and must be relit following manufacturer instructions carefully.

Condensation leakage can occur if you have a high-efficiency condensing furnace. The condensate drain lines should be checked for clogs which can sometimes lead to water pooling around your unit.

Finally, sensor malfunctions can cause erratic behavior in modern furnaces equipped with electronic ignitions systems - ensuring these sensors are clean often resolves such issues.

While many minor problems can be safely addressed with some DIY knowledge and cautionary measures taken beforehand, remember not all repairs should be undertaken on your own – especially when dealing with complex internal components or if you suspect a gas leak (noted by its rotten egg smell). In cases involving potential gas hazards or intricate electrical work within your furnace system, always call professional technicians who possess both experience and specialized tools for safe handling of such situations.

Regular maintenance helps keep common problems at bay - schedule annual check-ups with professionals who can perform thorough inspections ensuring everything operates smoothly throughout winter’s demanding conditions—keeping you cozy without unexpected interruptions.

Step-by-Step Guide to Cleaning the Furnace Components

A well-maintained gas furnace is the heartbeat of a warm and cozy home during the chillier months. Regular cleaning and upkeep not only ensure efficient operation but also extend the life of your furnace while preventing costly repairs and unsafe living conditions. This step-by-step guide will walk you through the process of cleaning your furnace components, ensuring that your heating system remains in top condition.

Before you begin, safety is paramount. Turn off the power to your furnace at the main circuit breaker and close the gas valve to prevent any accidents. It's also wise to have a professional inspect your system annually, but for routine maintenance, here’s what you can do:

Step 1: Replace or Clean Furnace Filters

Start by locating your furnace filter—typically found in the blower door compartment or between the blower and the air intake. If you’re using disposable filters, replace them with new ones that match size and type specifications for your model. If they're reusable, vacuum away loose debris before washing them with mild soap and water; allow them to dry completely before reinserting.

Step 2: Clean The Blower Assembly

After removing the front panel of the furnace to expose its interior, locate the blower assembly which usually sits behind where the filter was installed. Carefully remove it—some models may require unscrewing or unfastening clamps—and use a small brush along with a vacuum cleaner fitted with a hose attachment to clean out dust from around the blades.

Step 3: Check The Fan Belt

While you have access to this area, inspect the fan belt that connects the motor to the blower for signs of wear or cracks; if it seems damaged or overly loose, consider replacing it.

Step 4: Inspect The Burners

The burners are crucial as they directly heat incoming air. When cleaning these components, make sure they're free from dust accumulation which could lead to inefficient burning. You can gently brush off any dirt on them using a soft-bristled brush without disturbing their alignment.

Step 5: Clean The Flame Sensor Or Pilot Light

Your gas furnace might be equipped with either a pilot light or an electronic ignition system featuring a flame sensor. For pilot lights, ensure it's clear of debris so that it burns cleanly—a dirty pilot can cause short-cycling. If there's no pilot light present then locate and gently clean off any buildup from around your flame sensor using fine emery cloth; this helps in keeping accurate detection of flames within your unit.

Step 6: Clear Vents And Air Ducts

It’s important for airflow not to be obstructed within your ductwork; otherwise, efficiency drops significantly—plus there’s potential risk for fire hazards due to overheating parts inside confined spaces filled with flammable lint/dust particles.

Finally, once all internal components are clean and everything is back in place securely—with power still turned off—give exterior surfaces like covers/grills a wipe-down too so everything looks neat outside as well as operating smoothly on inside!

Always remember when doing any kind of work on appliances like furnaces where electricity/gas are involved—never take unnecessary risks! If unsure about any steps or encountering problems beyond basic maintenance tasks such as these described above then don’t hesitate seeking help from qualified professionals instead risking personal injury or damage property itself due lack experience proper tools/safety equipment needed handle such jobs safely effectively!

Replacing Faulty Parts: Igniters, Thermocouples, and Filters

Repairing and Maintaining Your Gas Furnace: Replacing Faulty Parts - Igniters, Thermocouples, and Filters

As winter approaches and the cold starts to seep into our homes, a reliable gas furnace becomes an essential comfort. However, like any other mechanical system, it's not immune to wear and tear. Routine maintenance and timely repairs are key to ensuring its longevity and efficiency. Three common culprits for furnace troubles are faulty igniters, thermocouples, and dirty filters. Understanding how to address these issues can save you from the discomfort of a cold home and costly professional services.

The igniter in a gas furnace has a critical job – it's responsible for lighting the gas that heats your home. Over time, an igniter can fail due to constant heating cycles causing it to become brittle or even break. If your furnace fails to start or you hear it cycling without producing heat, the igniter could be at fault. To replace it, first ensure that the power to the furnace is off for safety reasons. Locate the igniter within your unit; typically, it's situated near the burners. Gently remove it by disconnecting its mounting screw and electrical connector—take care not to touch the fragile element on the new igniter when installing it.

The thermocouple is another crucial component as it senses whether your pilot light is on or off and shuts down gas flow if no flame is detected — a vital safety feature that prevents gas build-up. Symptoms of a failing thermocouple include difficulty keeping the pilot light lit or frequent furnace shut-offs shortly after starting up.

DIY Guide: Repairing a Maintaining Your Gas Furnace - gas leak detection

- furnace filter upgrade

Finally, filters play an unsung role by cleaning air entering your furnace hence improving indoor air quality while protecting internal components from dust buildup which can lead to inefficiency or damage over time. A clogged filter restricts airflow causing strain on your system — so checking/changing them regularly (typically every 1-3 months) should be part of routine maintenance tasks anyone could do at home with ease: find where yours is located (commonly in return ducts), slide out old filter noting directionality marks/airflow arrows then insert new one accordingly.

In conclusion taking initiative with simple DIY fixes such as replacing worn-out parts like igniters thermocouples along with regular changes of filters not only keeps you cozy during chilly seasons but also extends life span of your investment into a warm household through efficient functioning of your gas furnace! Remember always prioritize safety by turning off power/gas supplies before attempting any work; consult owner's manuals thoroughly when in doubt; if tasks seem overwhelming don't hesitate seeking help from certified professionals who will get job done right with added peace of mind.

When to Call a Professional: Recognizing Jobs Beyond DIY Scope

When to Call a Professional: Recognizing Jobs Beyond DIY Scope

The world of do-it-yourself (DIY) can be immensely rewarding, giving you a sense of accomplishment and the potential to save money. However, when it comes to repairing and maintaining your gas furnace, it's crucial to understand where to draw the line between what you can handle yourself and when it's time to call in a professional.

Firstly, let’s acknowledge that working on a gas furnace involves risks such as exposure to natural gas or propane, carbon monoxide leaks, electrical hazards, and fire risk. These are not dangers to take lightly; they require respect and understanding. While routine maintenance like changing filters or cleaning vents may often be within the DIY realm for handy homeowners, more complex issues demand professional attention.

One clear sign that you need a professional is if you smell gas in your home. This could indicate a leak and is potentially dangerous. Evacuate immediately and contact emergency services or your gas company before calling for professional repair help.

Another scenario where expertise is necessary is if your furnace isn't igniting or producing heat. This could stem from various problems including malfunctioning ignition systems or faulty components like thermocouples or flame sensors. These issues involve intricate knowledge of the heating system's operation and safety protocols that professionals are trained for.

Also consider calling in experts if you're experiencing inconsistent heating or hearing unusual noises coming from your unit. A professional can diagnose problems with blowers, heat exchangers, motors, or other internal mechanisms that might not be apparent to the untrained eye.

Moreover, any task involving electrical work should give you pause; unless you have experience with wiring and understand how it interacts with your home's HVAC system thoroughly, leave this work for certified technicians who know how to navigate these complexities without causing damage—or worse—harm.

Maintenance inspections are also best left to professionals who can perform comprehensive checks on all components of your furnace system. They’re equipped with tools and knowledge needed for tasks such as checking for blockages in flue passages or testing the efficiency of burners which are beyond average DIY capabilities.

Finally yet importantly, consider warranty implications—a wrong move could void warranties provided by manufacturers on parts or even the entire unit. Professional servicing ensures that any repairs comply with warranty terms while upholding industry standards for safety and performance.

In conclusion, while embracing DIY projects around the house can be empowering—and even fun—when it comes to repairing and maintaining a gas furnace there are definitive boundaries one should heed. For anything beyond basic maintenance tasks like filter replacements or clearing dust from vents, bringing in professionals is not just about ensuring effective repairs—it’s about prioritizing safety for yourself and those living under your roof.