1. Regular Maintenance Checks

Prevention is better than cure, especially when it comes to complex appliances like gas furnaces. electrical wiring inspection Scheduling regular maintenance checks with a professional technician can help identify potential issues before they become serious problems. This includes checking the thermostat settings, inspecting electrical components and connections, lubricating moving parts, examining the condensate drain, and ensuring that all furnace filters are clean.

2. Thermostat Troubleshooting

Sometimes the problem isn't with the furnace itself but with the thermostat controlling it. If you're experiencing heating issues, check if your thermostat is on the correct setting and functioning properly. limit switch testing Replace batteries if necessary or reset your programmable thermostat according to manufacturer instructions.

3. Filter Replacement

One of the simplest yet most effective repair techniques is regularly replacing your furnace's air filter. A clogged or dirty filter restricts airflow and forces the furnace to work harder than necessary, which can lead to overheating and system failure. Check your filter monthly during high-use seasons and replace it as needed.

4. Pilot Light and Ignition Control Inspection

Older furnaces may have pilot lights that need to be lit manually if they go out while newer models have electronic ignition systems that can fail due to component malfunctions or power issues. For safety reasons, always refer to your user manual on how to relight a pilot light or troubleshoot ignition problems before attempting any repairs.

5. Cleaning Components

Keeping certain key components of your gas furnace clean can significantly improve its performance and longevity. This includes gently vacuuming dust from around the burner compartment, sensor rods, flame sensors (if accessible), and blower motor (after turning off power). Avoid disturbing wiring or sensitive parts without proper knowledge or guidance.

6. Checking Vents & Flue Pipe

Blocked vents or flue pipes not only reduce efficiency but also pose serious health risks by trapping dangerous gases like carbon monoxide inside your home instead of venting them outwards as intended.

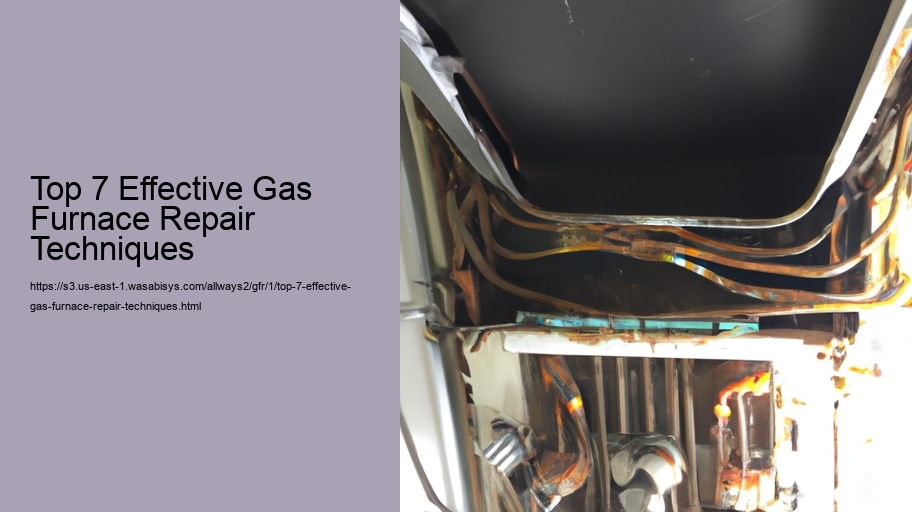

Top 7 Effective Gas Furnace Repair Techniques - heat exchanger inspection

- limit switch testing

7 Assessing Blower Belt Tension & Condition

A slack or damaged blower belt in a furnace impedes airflow through the system which affects overall operation efficiency – including heat distribution throughout your home – making this another pivotal point of inspection during troubleshooting efforts especially if you hear unusual noises emanating from within unit housing compartments where belts reside; proper tension adjustments replacement worn-out belts must be carried out accordingly ensure continued optimal function

In conclusion practicing proactive upkeep alongside possessing basic diagnostic acumen goes long way towards maintaining healthy resilient gas-furnace system These seven tips represent cornerstone strategies empowering individuals tackle common challenges associated with residential heating equipment With right tools knowledge hand many minor fixes performed safely effectively without immediate need resort full-scale professional intervention Remember though when doubt particularly concerning matters involving natural gases electricity always better err side caution seek assistance qualified experts ensure personal safety preserve integrity sophisticated heating installations