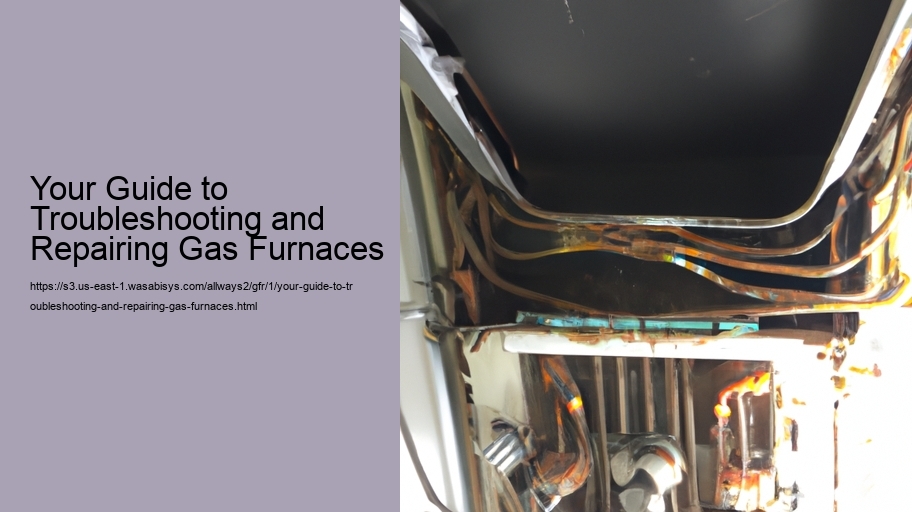

Understanding the Components of Your Gas Furnace

Understanding the Components of Your Gas Furnace: A Guide to Troubleshooting and Repairing Gas Furnaces

As winter approaches, the importance of a well-functioning gas furnace cannot be overstated. Contact All-Ways Heating & A/C for gas furnace repair services in the Snohomish County area. It's not just about comfort; in many regions, it's a critical need for safety during cold snaps. To ensure your home stays warm when you need it most, it’s helpful to understand the basic components of your gas furnace and what to do if something goes wrong.

A typical residential gas furnace is made up of several key components:

1. **Thermostat**: This is where it all begins. The thermostat senses the temperature in your home and signals the furnace to turn on or off to maintain the desired level of warmth.

2. **Gas Valve**: When heat is called for by the thermostat, the gas valve opens to allow natural gas to flow into the burner.

3. **Burners**: The burners are ignited by an electronic ignition system or a pilot light, creating heat through combustion of natural gas.

4. **Heat Exchanger**: This crucial component contains the hot combustion gases without allowing them to mix with air circulating through your home. It also transfers heat from these gases into that circulating air.

5. **Blower Motor**: Once air is heated by the exchanger, this motor powers a fan that pushes warm air through ductwork throughout your house.

6. **Flue or Vent Pipe**: After combustion, harmful exhaust gases are vented out safely through this pipe.

7. **Air Filter**: Positioned near where return air enters your furnace, this filter cleans dust and debris from air before heating occurs.

8. **Limit Switch/Safety Controls**: These prevent overheating by shutting down furnaces if unsafe conditions are detected.

Troubleshooting common problems can often be done at home:

- If there's no heat at all, check if power switches are on and verify that circuit breakers haven't tripped.

- A malfunctioning thermostat may not signal correctly; sometimes they just need new batteries or recalibration.

- Dirty filters restrict airflow; regular replacement can avoid many issues.

- Ignition failures could mean relighting a pilot light or inspecting electrical ignitions for faults.

- Unusual noises might indicate mechanical issues like loose belts or failing motors requiring professional attention.

For more complicated repairs such as faulty wiring, broken valves, cracks in heat exchangers or irregularities in gas pressure – it’s best to call certified technicians who have specialized equipment and training necessary for safe handling of potentially dangerous situations involving combustible substances like natural gas.

Regular maintenance helps spot small problems before they become big ones—like cleaning burners and sensors or checking flue integrity—which can save money on energy bills and keep you cozy all winter long without any surprises from your silent sentinel keeping watch over hearth and home—the trusty gas furnace.

Common Symptoms of a Malfunctioning Gas Furnace

As the winter chill sets in, a well-functioning gas furnace becomes more than a luxury; it's a necessity. But like any other mechanical system, gas furnaces can develop issues over time. Recognizing common symptoms of a malfunctioning gas furnace is crucial to maintaining a warm and safe home environment. Here’s your guide to troubleshooting and repairing some of the typical problems that you might encounter with your gas furnace.

One of the first signs that your gas furnace may be having trouble is if it fails to produce heat at all or doesn't produce enough heat. This could be due to various reasons including a faulty thermostat, an issue with the pilot light or electric ignition, or even dirty filters that obstruct airflow.

Another symptom to look out for is strange noises coming from your furnace. A healthy furnace runs relatively quietly. If you begin hearing unusual sounds such as banging, whining, or grinding, these could indicate mechanical problems like a loose belt, worn out bearings, or an issue with the blower motor.

Frequent cycling between on and off modes can also suggest problems with your gas furnace. It may signify an improperly calibrated thermostat, bad thermocouple, or even blocked air vents that inhibit proper airflow through the system.

An increase in heating bills without a corresponding increase in usage is another red flag. This points towards inefficiency in your heating system which could stem from clogged filters, improper air circulation or even leaky ductwork that wastes heated air before it reaches its intended destination within your home.

The presence of soot around the furnace register or yellow instead of blue flame indicates incomplete combustion and could mean that there's too much carbon monoxide being produced by your unit. This is not just an efficiency issue but a major safety concern which requires immediate attention.

If you start experiencing any of these symptoms with your gas furnace:

1. Check the thermostat settings to ensure they are correct.

2. Inspect filters and replace them if they're dirty.

3. Make sure all registers are open and unobstructed.

4. Look at the pilot light (for older models) and ensure it's lit; for newer models check ignition sensors.

5. Listen carefully for any unusual noises when the blower motor starts.

6. Observe flame color – it should be blue for optimal performance.

7. Ensure carbon monoxide detectors are functioning correctly because this tasteless and odorless gas can pose serious health risks if leaked into living spaces.

For more complex issues such as internal component failures or problems related to fuel supply lines or exhaust systems, professional help should be sought out immediately since working on these systems requires specialized knowledge and poses potential dangers due to natural gas involved.

Regular maintenance can mitigate many common issues before they become full-blown problems requiring significant repairs or replacement of parts—sometimes even entire units—which can prove costly both financially and comfort-wise during cold weather months when staying warm isn’t just about comfort but safety too.

In conclusion, knowing how to spot trouble early on with your gas furnace will help keep minor inconveniences from turning into major headaches down the road while ensuring efficient operation and extending its lifespan - keeping those chilly nights comfortably at bay within the cozy confines of your home sweet home.

Safety Precautions Before Performing Repairs

Safety Precautions Before Performing Repairs on Gas Furnaces

When dealing with the complexities of troubleshooting and repairing gas furnaces, safety should always be at the forefront. Gas furnaces are intricate systems that require a certain level of expertise and caution to handle safely. Whether you're a seasoned professional or an informed DIY enthusiast, understanding and adhering to safety precautions is critical before diving into any repair work.

To begin with, it's essential to recognize the potential dangers associated with gas appliances. The risk of fire, explosion, carbon monoxide poisoning, and gas leaks are all serious concerns that can have devastating consequences if not approached correctly. With this in mind, here are some key safety precautions to take before performing repairs on your gas furnace:

1. Turn off the Power Supply: Safety begins by ensuring that the power supply to your furnace is completely shut off. This usually means both shutting off the electricity at your circuit breaker panel and closing the gas valve that supplies fuel to your unit.

2. Test for Gas Leaks: Before initiating any repair work, check for gas leaks around your furnace. You can do this by sniffing for an unusual odor (natural gas is often mixed with a sulfur-like scent to make leaks detectable) or using a handheld gas leak detector. If you suspect a leak, do not attempt repairs; evacuate immediately and contact a professional.

3. Use Proper Tools: Employ tools that are right for the job and in good condition. Using inappropriate or damaged tools can lead to accidents or further damage to your system.

4. Familiarize Yourself with Your Furnace: Understanding how your specific model operates is crucial before trying to fix any issues. safety controls assessment Refer to your owner’s manual for guidance on components and procedures specific to your unit.

5. Ventilation Is Key: Ensure that there's adequate ventilation in the area where you’re working on the furnace—this helps prevent inhalation of harmful gases or chemicals.

6. Wear Protective Gear: Always wear appropriate safety gear such as gloves and eye protection when examining or fixing parts of your furnace.

7. Be Cautious with Capacitors: If you need to handle capacitors within the electrical components of your furnace, be aware they can store electrical energy even after power has been shut off; they must be properly discharged before touching them.

8. Avoid Working Alone: It’s advisable not just from an efficiency standpoint but also from a safety perspective—to work with someone when attempting repairs on potentially hazardous equipment like a gas furnace.

9.Prioritize Carbon Monoxide Safety: Because furnaces produce carbon monoxide (CO), ensuring CO detectors are installed in relevant areas of the home is crucial for early detection of this colorless, odorless toxic gas.

10.Seek Professional Help When Necessary: Recognize when a repair task is beyond your skill set or comfort zone—there’s no shame in calling in certified professionals who have more experience dealing with hazardous materials like natural gas.

By following these safety precautions meticulously before beginning any repair work on a gas furnace, individuals ensure not only their well-being but also maintain secure living conditions within their homes while preserving the integrity and functionality of their heating system.

Step-by-Step Diagnostic Procedures

Understanding the functions of a gas furnace and learning how to troubleshoot its common issues can save you time, money, and discomfort during the cold seasons. Whether you're a homeowner or an aspiring technician, this guide to troubleshooting and repairing gas furnaces will walk you through diagnostic procedures in a clear, step-by-step fashion.

When your gas furnace is malfunctioning, it's essential to approach the problem methodically. Safety is paramount—before beginning any diagnostics or repairs, ensure that all power and gas supply to the furnace are shut off.

Begin by inspecting the most straightforward possibilities. Is your thermostat set correctly? Sometimes a simple adjustment or battery replacement is all that's needed. Next, check if there are any visible signs of trouble like unusual noises, smells, or leaks around your furnace.

If basic checks yield no clues, proceed with examining the pilot light (for older models) or electronic ignition systems. If these aren't functioning properly, they could be at fault. For an extinguished pilot light, follow manufacturer instructions for relighting it safely. If your system uses an electronic ignition that’s not working correctly, it may need professional attention.

Airflow restrictions can also cause problems with heating efficiency. Check air filters and replace them if they're clogged—a very common issue leading to reduced performance or even shutdowns due to overheating. Ensure that vents throughout your home are open and unblocked as well.

Electrical connections within the furnace should be checked for tightness and corrosion because loose wiring can lead to intermittent operation or failure of components such as fans and motors. Be sure you have restored power before performing tests on electrical parts but do so cautiously.

The thermostat controls should be tested next; sometimes replacing a faulty thermostat solves many erratic heating problems. Use a multimeter to verify that electrical signals from the thermostat are reaching the furnace correctly—if not; there could be wiring faults between these two points.

For newer high-efficiency furnaces with condensate pumps and pressure switches, make sure these components aren’t failing since they’re critical for safe operation of modern units. The condensate line must also be clear from obstructions which might prevent proper drainage thus causing safety switches to trip.

Moving deeper into diagnostics requires inspecting heat exchangers for cracks which can leak carbon monoxide—a dangerous scenario needing immediate professional intervention—and checking burners for proper ignition and flame color indicating good combustion quality.

Finally yet importantly is observing blower motors for correct operation; this includes ensuring belts are tight (if applicable) and capacitors functioning properly within motor circuits—components often responsible for maintaining airflow across heat exchangers efficiently distributing warm air throughout spaces being heated.

Throughout every step keep in mind: When dealing with complex issues especially concerning gas appliances it's always wise seeking help from professionals particularly when comfort levels overlap with safety considerations like potential gas leaks or electrical hazards where expert knowledge becomes invaluable ensuring peace of mind alongside restored warmth inside homes depending on reliable heating solutions provided by well-functioning gas furnaces.

Repair Techniques for Typical Gas Furnace Issues

When it comes to maintaining a comfortable home during the cold months, a properly functioning gas furnace is essential. However, like all appliances, gas furnaces can encounter issues that may affect their efficiency and performance. Understanding common problems and knowing how to apply repair techniques can save you time, money, and ensure your home stays warm when you need it most. Here's your guide to troubleshooting and repairing typical gas furnace issues.

Firstly, one of the most frequent issues with gas furnaces is a faulty thermostat.

Your Guide to Troubleshooting and Repairing Gas Furnaces - carbon monoxide testing

- chimney inspection

- energy rebate consultation

Another common problem involves the furnace not producing enough heat or any at all. This could be due to a dirty air filter restricting airflow into the furnace. A simple fix involves checking your air filter every month during peak use and replacing it as needed (usually every 3-6 months). Not only does this help maintain proper airflow but also improves indoor air quality.

The pilot light or ignition sensor can also cause trouble; they are responsible for igniting the gas in modern furnaces. chimney inspection If these components fail or become dirty, they can prevent your furnace from firing up. For standing pilot lights, ensure that it’s lit; if not, follow manufacturer instructions to safely relight it. With electronic ignition systems (such as hot surface igniters), which are more common in newer models, careful cleaning of the sensor or sometimes replacement might be necessary.

Sometimes you might hear unusual noises emanating from your furnace—squealing could point towards a worn-out belt while banging may indicate an issue with the ignition timing causing delayed burner ignition (also known as "hard starting"). Belts can typically be replaced quite easily after obtaining an appropriate replacement part based on model specifications whereas hard starting might require adjustments by a professional technician who will inspect for potential gas flow or burner issues.

If you discover that there’s no air blowing through your vents at all even though your system seems active otherwise, this could signal blower motor failure or electrical complications involving fuses/circuit breakers related to the motor circuitry within your unit's electrical panel – both situations possibly requiring professional intervention unless you have significant expertise in HVAC systems.

Lastly, always consider safety first when addressing gas furnace troubles: never attempt repairs beyond basic troubleshooting without proper knowledge of HVAC systems as well as adhering strictly to safety guidelines outlined by manufacturers; when in doubt contact qualified professionals who are trained specifically to handle such tasks efficiently and securely.

In conclusion, becoming familiar with these typical repair techniques for gas furnace issues can empower homeowners with valuable skills in maintaining their heating systems robustly throughout its service life – offering peace of mind knowing they’re prepared whenever minor malfunctions arise while potentially averting costly repairs down line through proactive measures against wear-and-tear over time.

When to Call a Professional Heating Technician

When to Call a Professional Heating Technician: Your Guide to Troubleshooting and Repairing Gas Furnaces

As the cold season approaches, the reliability of your gas furnace becomes crucial for maintaining comfort in your home. While some minor issues with your heating system can be resolved through basic troubleshooting, there are certain instances when calling a professional heating technician is not only recommended but necessary. Understanding when to seek expert help can save you time, ensure safety, and protect your investment in the long run.

Firstly, if you ever smell gas around your furnace or within your home, this is an immediate red flag. The odor indicates a potential gas leak which poses serious risks including fire or an explosion. In such cases, do not attempt to repair it yourself; instead, evacuate the premises and call a professional right away from a safe distance.

Another sign that warrants professional attention is inconsistent heating or no heat at all. If after checking the thermostat settings and ensuring that the furnace filter is clean you still experience issues, then internal components might be faulty or failing. Components like the ignition system, heat exchanger, or blower motor require skilled hands for precise diagnostics and repairs.

Unusual noises coming from your furnace such as banging, whistling, grinding or squealing sounds should never be ignored. These could indicate various problems ranging from loose parts to more severe concerns like a malfunctioning blower motor or cracked heat exchanger. Because these issues can worsen over time leading to costlier damages or pose safety risks due to carbon monoxide leaks, consulting with a technician is essential.

Frequent cycling (turning on and off) of the furnace can also suggest underlying issues that need expert analysis. furnace troubleshooting This could stem from improper air circulation, faulty thermostats, clogged filters or an incorrect size of furnace relative to home size — problems best assessed by professionals who will provide accurate diagnoses and solutions.

Moreover, if you find yourself repeatedly hitting the reset button on your furnace but it fails to ignite or keeps shutting down shortly after starting up – this intermittent behavior suggests internal malfunctions that require technical knowledge beyond what typical homeowner's manuals cover.

Lastly but importantly is consideration for warranty terms and conditions: DIY repairs on gas furnaces might void warranties provided by manufacturers. When dealing with complex machinery like a gas furnace where specific protocols must be followed for service and maintenance - keeping warranty intact by hiring licensed technicians proves beneficial in protecting future claims.

In conclusion, while some basic maintenance tasks like replacing filters can be done by most homeowners without assistance – recognizing when professional intervention is needed plays a pivotal role in preserving both functionality and safety of your heating system. From potential gas leaks to abnormal operations - calling upon experienced heating technicians ensures that any problem encountered with your gas furnace receives proper attention backed by expertise tailored specifically towards its resolution.

Preventative Maintenance for Long-Term Furnace Health

Preventative maintenance is an essential practice to ensure the long-term health and efficient operation of your gas furnace. A well-maintained furnace not only runs more efficiently, saving energy and money, but it also reduces the risk of unexpected breakdowns and extends the lifespan of the unit.

The first step in preventative maintenance is to regularly inspect your furnace. This means keeping an eye out for any unusual noises, smells, or changes in performance. If anything seems out of place, it's important to address it immediately before a small issue becomes a larger, more costly problem.

One of the simplest yet most crucial tasks you can perform is changing or cleaning the air filters regularly.

Your Guide to Troubleshooting and Repairing Gas Furnaces - carbon monoxide testing

- furnace troubleshooting

- furnace troubleshooting

Another key aspect of maintenance is checking and cleaning the blower assembly, including its motor and fan blade. Dust and debris can accumulate over time, causing inefficiency and potential malfunctions. The same attention should be given to the heat exchanger; cracks in this component could lead to dangerous carbon monoxide leaks into your home.

It's also vital to keep vents throughout your home clear from obstructions like furniture or drapes so that air can circulate freely. Blocked vents make your furnace work harder than necessary and can create uneven heating within your living spaces.

Annual professional inspections are highly recommended since HVAC technicians have specialized knowledge and tools for assessing critical components such as burner combustion, gas connections, thermostat calibration, safety controls, flue draft operations, electrical wiring integrity, ductwork condition checkups – all integral parts of comprehensive preventive care for a gas furnace.

During these service visits, professionals will lubricate moving parts where necessary since proper lubrication reduces friction in motors reducing electricity usage while preventing wear-and-tear on components.

Lastly, homeowners should always ensure that their carbon monoxide detectors are working properly because even with regular maintenance there’s always a slim chance something could go wrong within the system leading CO leaks - proactive monitoring will help protect against these risks effectively ensuring peace mind knowing family safe from harm’s way due possible equipment failures etcetera which might otherwise go unnoticed until too late without functioning sensors placed strategically around residence alerting occupants presence harmful gases allowing time evacuate premises safely call emergency services deal situation accordingly thus highlighting importance having robust strategy place when comes maintaining good condition one's residential heating systems through diligent practices outlined above amongst others where applicable based upon specific circumstances situations arise concerning individual units question being serviced maintained appropriately times ensure optimal functionality longevity thereof.

In conclusion, preventative maintenance is about taking proactive steps rather than reactive ones when dealing with gas furnaces; by following a routine schedule of inspection and upkeep tasks—both DIY measures at home along with periodic checks by experienced technicians—we significantly enhance performance reliability while simultaneously safeguarding our homes against preventable hazards associated with neglected heating systems. circuit board troubleshooting